I. A Note on Rotary Evaporation from Dave Arnold

II. The Purpose of Rotary Evaporation

III. Development and Evolution of The FCI’s Rig

IV. How Rotary Evaporation Works

V. Some General Theory

VI. Basic Rotovap Structure and Design

VII. Rotovap Pimpage

VIII. Operation: Flying the Rotovap

IX. Recipes

I. A Note on Rotary Evaporation from Dave Arnold

The distillation of alcohol is probably illegal where you live (unless you live in New Zealand). Many people cannot believe that this practice is illegal. It is. “Isn’t there an exception?” they’ll say, or, “can’t you make a small amount for personal consumption?” No. Distillation is defined as the separation of ethanol from a mixture containing ethanol, and you can’t do it without a license. That license is almost impossible to obtain. You can easily get a fuel-alcohol license, but then you’re obliged to render the product unfit for consumption.

The U.S. laws were written to prevent people from not paying taxes on distilled liquor. Since I have already paid alcohol taxes on 100% of the products I use, and I don’t ship or resell them at a higher proof, I feel I am adhering to the spirit, if not the letter, of the law. I have heard people say that the distillation laws are also in place to prevent accidents (conventional distillation with open flames can be quite hazardous), but I disagree. I’m allowed, by law, to light a cigarette and bungee jump off a bridge over a tanker of kerosene if I want to.

Just to beat the point further: If you are reducing port wine in a pot: legal. If you put a lid on the pot: legal. If the lid should be ajar and some of the condensate should drip in a cup next to the pot: illegal.

Owning a rotovap is legal. In the US you are allowed to own a still with capacity under a gallon without having to register it. This allows for the distillation of volatile oils, waters, etc. Our rotovap has a three liter capacity so we’re in the clear.

Most chefs try to stay on the right side of the law and don’t perform distillation with alcohol. This is unfortunate because alcohol is a fantastic medium for carrying flavor and volatile aromas. Products distilled under strictly aqueous (water) conditions just don’t taste as good. I have distilled the same flavors in a water base and an alcohol base—there is no comparison. Water-based distillations often have a good nose, but they are very weak in flavor.

At The FCI, we do distillation in alcohol, even when it’s for culinary purposes. Aside from the fact that alcohol is a great flavor carrier, the mixture of alcohol and water has a constantly changing boiling point, which, I think, helps to capture a wider range of aromas and flavors than you would get out of a single-boiling-point mixture. (This is my own theory, and I invite your comments and opinions on this point.) The flavor of water-based distillations also tends to fade quicker than those done with alcohol. Pineapple juice distilled with water loses its aroma after only an hour or two. I suppose it would be possible to get good results by distilling a mixture of water and acetone, or a similar disgusting, poisonous solvent, which would be legal, but I wouldn’t serve it, even if all the solvent could be evaporated later.

Aside from the flavor benefits of alcohol, it is also much easier to distill than water. It takes 2.6 times as much energy to vaporize water than ethanol, and you have to remove 2.6 times as much energy to convert that vapor back to a liquid. Other than saving energy, the upshot is that I can do more liters per hour of ethanol than I can of water using the same rig.

II. The Purpose of Rotary Evaporation

In both traditional chemistry labs and our culinary technology lab, the rotary evaporator, or rotovap, is an instrument used to distill a solvent. (Everyone calls it a “rotovap” even though rotovap is a brand name). The purpose of distillation is to separate a given mixture into its components based on their respective volatilities, through the process of evaporation and condensation (liquid-gas-liquid).

We use the rotovap for two main purposes: 1) to concentrate non-volatile components in a mixture (for example, concentrating the purest and freshest flavors from a blood orange by removing the water), and 2) to extract the volatile aroma and flavor molecules from mixtures gently and at low temperatures (for example, extracting the desired flavors from a blend of alcohol, herbs, and fruit without heating the mixture up).

The key to understanding any distillation is to remember that it is a separation. Sugars, acids, colors, and most bitter compounds are separated from aromas, alcohols, water, and small flavor molecules, etc. What is phenomenal about rotovap distillation, as opposed to standard distillation, is that it can separate food compounds from one another without altering them.

Two key components of the rotovap allow for a gentle, precise, and efficient distillation not found in conventional distilling apparatuses: 1) the solvent is removed under vacuum, which lowers its boiling point, eliminating the need for high-temperature distillation, and 2) the rotation of the evaporating flask, immersed in a heated water bath, increases the surface area of the product, greatly speeding distillation and also, through forced convection, keeping the mixture evenly mixed and heated to promote stable, even evaporation.

An additional benefit of laboratory-type stills over Uncle Jesse moonshine-type pot stills is that laboratory condensers, being sealed and made of glass, are easy to visually monitor and adjust. We can, therefore, recover almost 100% of the solvent.

While scientists are almost solely concerned with the residue left over after the solvent has evaporated, we are proud members of the minority interested in the distillate itself. What they call a solvent, we call flavor. To this end, we have redesigned a mid 1980’s vintage Buchi Rotovap EL-130 and tailored it to our culinary endeavors. Therefore, beware! The primer that follows is not a standard rotovap primer. It is a primer for those individuals interested in distilling not petrochemicals, but gin. And it’s not a primer on standard distillation, which is usually concerned with maximizing the purity of the distillate. We want to maximize the impurity. But we get ahead of ourselves. Let’s start with an overview of the distillation process

III. Development and Evolution of The FCI’s Rig

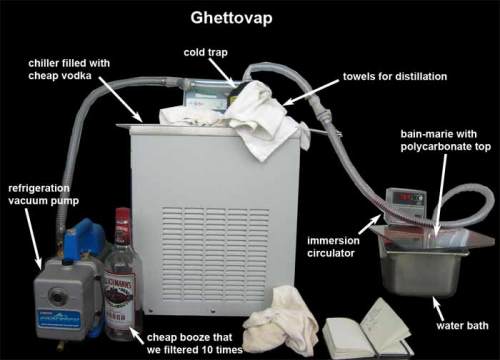

I first started experimenting with vacuum distillation in 2005. I didn’t have a rotary evaporator so I just attached a bain-marie to a cold-trap/chiller and a refrigeration vacuum pump (see photo).

This setup was awful. I made some good products with it, but it was a pain in the butt to run: I frequently contaminated my products with oil vapors (I hadn’t yet learned the proper procedure for using an oil-based pump); my product boiled over all the time; I couldn’t see what was going on; I could tell I was losing aroma because the whole kitchen smelled like port wine (my current rotovap has no smell when things are running perfectly); and I had to agitate the bain-marie by hand to keep the distillation going. No fun.

In January 2006 I went to Madrid Fusion and saw Joan and Jordi Roca do a demo with their rotary evaporator. Those guys are great. I knew some chefs had rotovaps but this was the first time I had ever seen a chef demo one. I was amazed by how quiet it was (even our current model is loud because of all the pumps we have running). One of the dishes they demoed rotovapped dirt from their local forest into a clear, dirt-scented water that they put on oysters—surf and turf with literal local terroir. Very poetic. I later cornered Joan Roca and asked him about the dish. He said he wanted the experience of the dish to be akin to what it is like to smell the fresh earth after a rainstorm as a child would—perceiving the whole world as new. I knew I needed to get a rotovap badly.

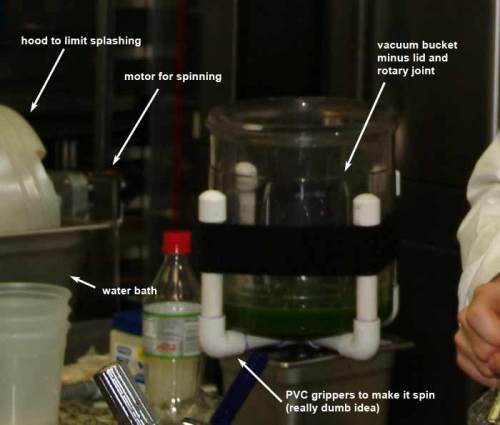

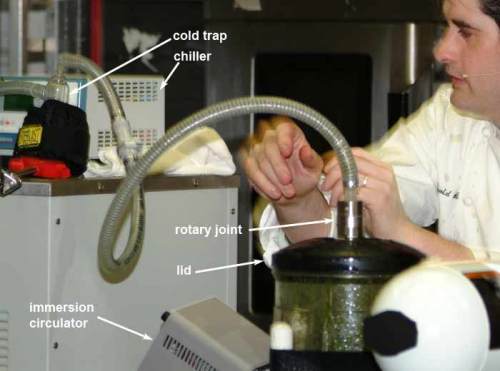

Unfortunately, I couldn’t convince the powers-that-be to buy a rotovap for me at The FCI and we didn’t want to go full eBay yet (too scrappy for the school), so I built a modified “rotoghettovap” for a PastryScoop.com event I did at The FCI with Sam Mason in the spring of 2006. It took the same basic setup as before but added a spinning vacuum chamber (a hacked up vacuum marinating machine and a rotary valve from McMaster-Carr). No full pictures survived, but here are some shots from the demo:

Of course, this system had problems:

After this demo, I decided to buy a used rotovap on eBay with a couple hundred bucks of my own money. I soon realized that the receiving flask was the weak-link of rotovap flavor (more on this later), so I built an adapter which allowed me to pump out the distillate as I was going. (We are looking into patenting this idea.) Finally, I found a $3500 vacuum controller and pump on eBay for $150. Here is the full setup as Nils and I were using it mid-2007:

This system has remained fairly stable since then. Future plans include building a kitchen friendly rotovap from scratch. I have a lot of ideas on how to make it better—and cheaper. If you had to buy my rotovap using all new parts you’d end up spending $18,000. Ouch. Even so, I love the rotovap. It is my favorite piece of kitchen equipment. It allows me to create flavors that would otherwise be impossible.

One more personal note: Be careful with the glass! It always breaks when you need it. Then you need to pay full price because you can’t wait for the eBay auction. My distillation flask ($300) has broken twice. The glass part that connects the condenser to the rotovap itself costs $350. It has only broken once, but it happened during a demo (it just slowly crushed in on itself).

Now, on to the primer.

IV. How Rotary Evaporation Works

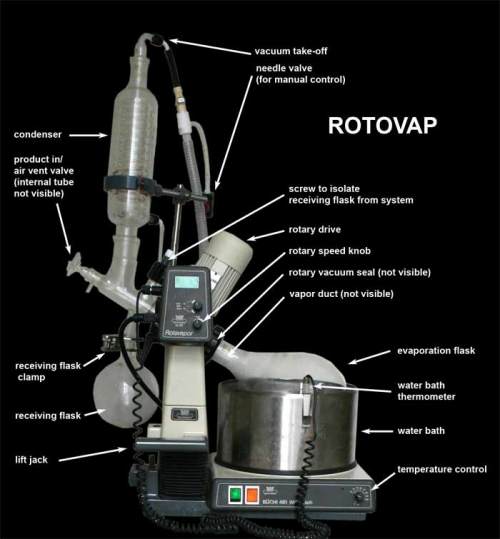

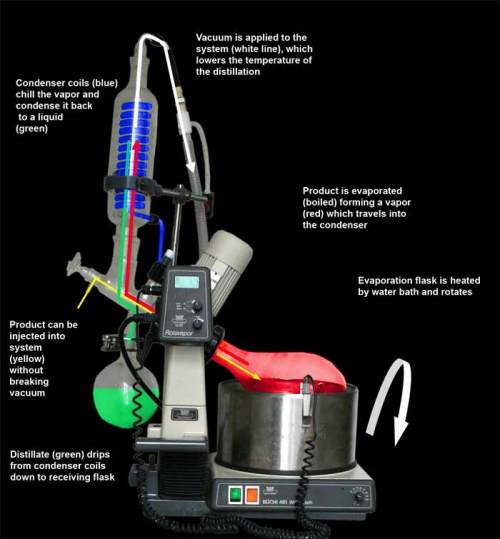

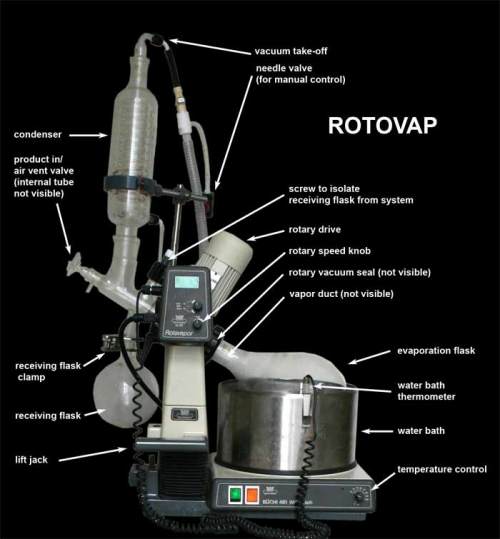

Here is the basic rotary evaporator setup. We’ll go into greater detail on some of these parts in Section VI.

And here’s what happens during distillation:

V. Some General Theory

Before getting into greater detail on the rotovap process, it is important to understand the theory behind the instrument. Four components affect the rate of distillation:

1. Temperature of the Heating Bath: The higher the temperature of the bath, the faster your product will boil at a given pressure. The boiling temperature of your product is determined by the pressure of the system. A higher water bath temperature will not raise the temperature of your product above boiling, but it will put in energy faster. In standard distillation, the pressure is kept constant and the temperature of the product slowly rises with time as more and more product boils off; the rate of distillation is determined by heat input. In a rotovap, the temperature of the heat input (and, roughly, the temperature of the product) is kept constant and the distillation is adjusted by controlling the pressure.

2. Pressure of the Distillation: The lower the pressure, the lower the boiling point of your product and the faster you will distill at a given bath temperature (i.e., at a given heat input).

3. Speed of Rotation and Size of the Flask: Generally, the larger the flask and the higher its RPM, the quicker the evaporating process (there is more new surface area exposed per unit time).

4. Size and Power of the System: The speed of distillation in a given system is limited primarily by the condenser’s ability to condense the solvent vapor (it is rare to be limited by the heater). If you allow too much vapor to rush into the condenser, it will overload and be unable to work efficiently, which will result in a loss of valuable volatiles. According to the manufacturer Buchi, to avoid saturation, you should monitor the pressure of the system such that 2/3 of the condenser is consistently covered with condensate. If liquid begins to form on the top 1/3 of the coil, the incoming vapor runs the risk of being sucked out into the vacuum pump and being lost forever. In practice we often let the condensation get closer to 3/4 of the way up the condenser. Another indicator is the “condensation line,” usually above the area where you see actual liquid on the coils. This is easy to see in water distillations, but hard to see in alcohol distillations. Here is a good one:

Unfortunately, it takes a while to become comfortable adjusting the pressure. Until then, your “get out of jail free card” is the “air button.” A quick push of this button will raise the system pressure, clearing the condenser and allowing you to start afresh.

The speed of distillation is important because the faster you distill without saturating, the better the flavor. This is a fact.

Note: what follows is a theory; feel free to comment.

Many of the flavor components we are trying to capture are present in minute quantities. Fast distillation produces a steady constant “rain” of distillate inside the condenser. This massive amount of condensation does a better job of capturing those minute quantities of flavor chemicals than a slow distillation, where there is more transit time in the condenser and greater opportunity for flavors to exit into the vacuum system without condensing at all.

The size of your condenser and the size of your evaporation flask work in tandem, along with the optimal batch size for a given distillation. Approximately one liter of liquid per mixture creates the optimal condensing conditions for our rig. If you use considerably more, the evaporation flask will be overly full. You risk boiling over in the distilling flask, and also lose the effect of the rotating flask to increase the surface area being heated. If you use considerably less product (like a puny couple hundred ml), you cannot achieve enough condensation to form a rain of distillation in the condenser.

VI. Basic Rotovap Structure and Design

Now we’ll revisit some key components of the rotovap, providing more details on our own setup and tips to help you build your own.

Evaporation Flask: The mixture to be evaporated starts in this flask, which rotates in a heated water bath. The size of your flask determines how much liquid you can distill at one time. Bigger is better, so long as your condenser can handle it. Ours is 3 liters.

Ideally, you want to attach the flask to the rotovap first, and then pump the solvent directly in (more on why in Section VII). Don’t fill the flask more than half full or you’ll have problems with boil-over. And you’ll decrease surface area and slow down distillation. Our flask has a special wide neck, which makes it easy to get product in and out. If your machine can’t accommodate a 3-liter flask, invest in an evaporation beaker, a wide mouth beaker that can be hooked up to a rotovap.

Rotary Drive: Controls the rpm of the flask. We keep ours at around 120.

Water Bath: Filled just up to the point where the mixture in the flask is submerged, the water bath transfers heat to the mixture quickly and efficiently. Water is the optimal medium to use since it’s safe and cheap, distributes heat well, and has a high specific thermal capacity (though on certain occasions, it may be necessary to heat the mixture using an oil bath).

Vapor Duct: This is where the vapor is transmitted from the evaporation flask to the condenser. It is also where your system is most likely to leak. Make sure your vapor duct is super-duper clean and properly centered. On our EL model, the vapor duct is stationary, and the seal rotates around it, as opposed to most other models, where the seal is stationary and the vapor duct rotates. This difference won’t make matter to most people, but since the EL series aren’t made anymore, they are often cheaper. They also allow reflux distillation (for the hard core rotovap users out there), but the seal goes bad on them more often.

Rotary Vacuum Seal: These cost 50 bucks a pop for a tiny ring of rubber so take good care of them! Remove the seal from the rotovap when you’re not running it. The manufacturer says to never grease them because grit can get into the grease and ruin the vapor duct. We do anyway because is the only way we can get the seal to work. Make sure you install them the right way (check your manual for details).

Condenser: As solvent surrounds the condensing coil with vapor, this part of the instrument turns the vapor back into a liquid (using the same amount of energy to cool that was originally needed to heat the liquid into a vapor). The vapors condense into liquid droplets that, by the power of gravity, make their way down the coil into a receiving flask.

You need enough cooling power in the condenser to condense everything that has vaporized in the evaporation flask, or the condenser will get saturated. This will contaminate your pump and make the mixture lose flavor. The more cooling power your condenser has, the more liters per hour you can distill without saturating and without losing temperature. There is no point, however, in having more cooling capacity than you have heating capacity in the water bath.

Another type of condenser is the “cold finger,” which consists of a sleeve filled with extremely cold liquid, like liquid nitrogen or dry ice and acetone, instead of a coil. Cold finger condensers completely freeze the distillate. They get extremely good capture of the volatile aromas, but I don’t like them because you have to thaw them out between batches. And there is no way to tell when you are done because you can’t taste the product as you go (more on that later).

Vacuum Pump/Controller: The rotovap would be just a souped-up still if it weren’t for the vacuum pump. The vacuum is what lowers the boiling point of product and allows us to do distillations all the way down to room temperature or below.

Choosing a good pump is important. First, your pump needs to be powerful enough to obtain a reasonable vacuum in a reasonable amount of time. Second, your pump needs to be able to reach an ultimate vacuum (the highest level your machine has the ability to achieve) good enough for the work you are doing. Atmospheric pressure is about 1000 millibar. To do straight liquor work at 60°C, your pump needs to be able to go down to 40 millibar without breaking a sweat. To do all liquor work down to 40°C your pump better be able to pull an ultimate vacuum of 20 millibar. To do syrups or for water-based work, your pump better get down to 8-10 millibar. Most people fail by getting a pump with an inadequate ultimate vacuum.

Water aspirators will not work for low temperature distillation; they also have low flow rates. I have tried using them with ice water, in big banks, etc. I don’t like them. Refrigeration vacuum pumps work well and are cheap, but are difficult to control, noisy, and fill the air with an oil-haze (pictured in the ghettovap image in Section III). They need oil to operate and don’t come with a filter, like the pumps in a vacuum sealer. If you do decide to use one, leave a rag over the outlet to catch oil. Also never, ever turn off the pump when under vacuum or you risk sucking oil back into your system. First vent the system, and then turn off the pump. To control a refrigeration pump, you need to install a bleeder needle valve between the pump and the rotovap. Let the pump run and adjust the vacuum level using the valve. Also install a second air/vent valve, preferably push-button. This is your emergency button that quickly lets air into the system to stop a boil-over. Other than noise, oil-haze, and control difficulties, the other problem with oil-based pumps is that the oil gets contaminated whenever you saturate the condenser.

Much better than an oil based pump is a dry vacuum pump and a vacuum controller. They are quieter, cleaner, easier to control, and don’t get contaminated. A dry pump with a good vacuum control is such a pleasure; you’ll never want to go back to the needle valve/oil-pump routine! The problem is the control units cost thousands of dollars and the dry pumps alone are many hundreds. We use an Ilmvac pump/control unit that retails for $3500. (Thanks, eBay!) See the image of our current rig in Section III. Most controllers have an “automatic” distillation function that finds the correct vacuum level for your current product. I don’t like these. I’ve used several companies’ controllers and find that having a human being control the distillation level consistently delivers a higher quality product. It is a huge timesaver, however, to let the machine do the thinking for you. I think it would be possible to design a controller for maximum flavor; but it hasn’t been done yet.

Product In/Air Vent Valve: This valve, when turned down, uses the vacuum in the system to suck product into the evaporation flask without breaking the vacuum. It’s very handy. The internal tube is quite small so don’t try to suck anything through it that hasn’t been strained. Turn the valve in the other direction to let air into the system. When you are starting you can use this as your “emergency button,” but I don’t recommend it. It’s not fast enough and requires that you reach up and twist it, as opposed to the air valve attached to the vacuum pump.

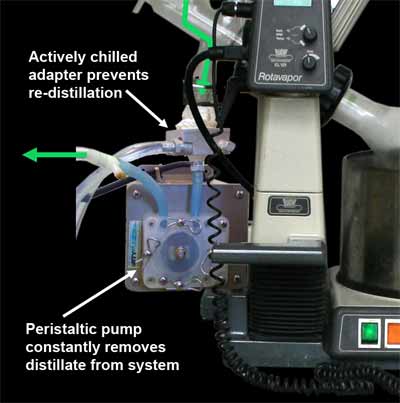

Receiving Flask: This is where the distillate goes. It’s the flavor killer, the Achilles heel of the standard rotovap. The distillate tends to redistill into the condenser and then back down again into the flask. Each time this happens a little flavor gets lost out the top of the condenser (we don’t re-condense 100%). This dilutes the flavor of the final product, as the result averages out to whatever the main solvent is (usually alcohol and water). This isn’t a problem for scientists, who only dealing with one or two solvents. But for us, the “solvents” are all the volatile flavor and aroma compounds! There can be dozens of these compounds in a single distillation. Some are only present in tiny quantities but are key to the final flavor. To improve your results, chill the receiving flask and remove it often to dump out the distillate. To really solve the problem, read on.

VII. Rotovap Pimpage

Here are some additional modifications that will help you get the most out of your rotovap.

Cooler: The temperature of the heating bath and the pressure of the distillation must work in concert in order to distill the desired volatile elements of a given mixture. By lowering the pressure of the system, you can boil the mixture at a considerably lower temperature. We keep the temperature of the water bath consistent and adjust the pressure such that the condensate can form optimally and we can capture the purest distillate.

As a general rule, the temperature difference between the water bath and the condenser should be at least 40°C, but the higher the temperature difference, the more completely we recapture flavors. The Buchi manual recommends keeping the water bath at ~60°C and the cooling water at ~20°C (about as cold as tap water gets). In order to do distillation below 60°C, we have installed a chiller that lowers the condenser’s temperature to -20°C. While this temperature inevitably rises to between -8°C and -12°C by the end of the distilling process, this temperature differential between the water bath and condenser is still sufficient to produce the most complete distillation.

In fact, the warmer temperature at the end of distillation is a benefit. Most of our distillations start with ethanol and end with water, which means a constant temperature of -20°C would freeze our distillate. Originally, we ran our chiller on gin so bad it was considered unfit for human consumption. Alcohol, however, doesn’t provide very good chilling power (it doesn’t store energy well), so we switched to a mixture of propylene glycol and water. You can get propylene glycol from McMaster-Carr in 5-gallon containers. Don’t use ethylene glycol, as it is nowhere near food grade. Polyscience makes a good rotovap chiller (see the ghettovap image in Section II).

Peristaltic Pump: Traditional rotovaps catch the distillate in a receiving flask. As we said before, this is a flavor killer. We decided to remove the flask entirely and replace it with a peristaltic pump that pumps out the distillate as it is formed. The unadulterated distillate then flows through a tube into a receiving flask/bottle, external to the pressurized system. Originally, we installed the peristaltic pump to a non-cooled adapter. We have since built a chilled aluminum adapter and the flavor is even better.

For our purposes, flavor is king, and this new setup helps our endeavor greatly. Instead of guessing as to when we should stop the distilling process, we can taste the distillate in real time, at multiple points as it is formed, to ensure that we are getting the best possible flavor. We can then cut off the distilling process the moment our distillate begins to take on flavors we dislike. The adapter/pump setup is our primary innovation and what separates our rig from the rest.

Peristaltic pumps are one of the only pump types that can pump liquids out of a vacuum to atmospheric pressures that are available at a reasonable price. They are also non-contaminating since the product only touches the tubing. Our peristaltic pump uses 1/4-inch ID tubing. We have also tried Norprene, Tygon, Silicone, Buna N Rubber, Polyurethane, etc. Norprene is good but expensive. Don’t use the black tubing or you’ll end up with black particles in your distillate. Our current favorite is transparent-blue polyurethane that we get from McMaster-Carr. Transparent tubes are good because you can see what’s going on.

The one problem with peristaltic pumps is that the tubing can collapse when the pressure is very low (hit the air button and it will open up again), or when the tubing is old (time to replace the tubing). Don’t get in the habit of leaving the tube in overnight because it weakens the tubing. Also, don’t run it for long periods dry, which heats up and weakens the tube.

VIII. Operation: Flying the Rotovap

Here’s the information you’ve been waiting for: a long, nitty-gritty section on flying the rotovap.

Correct Order to Set Up a Rotovap

Plug water bath, rotovap, peristaltic pump, and vacuum pump into one 20 amp circuit. Plug chiller into separate 15-20 amp circuit. Do not attempt to run entire system off of one circuit. Turn on chiller and allow it to reach temperature. Fill water bath (usually 2/3 full) with warm to hot water, set the temperature and turn it on. Put the thermometer from the rotovap unit into the water bath. Clean the vapor duct area and install the vacuum seal. Install a DRY evaporation flask. Close off (seal) the receiving flask/pump takeoff area. Close the product in/air vent valve.

If some numbskull turned the bath on without water, you’ll need to reset the bath. There is usually a hole big enough for a paper clip in the front panel of the bath. Stick a paper clip in there. The heater indicator should come on.

Perform Vacuum Test

With the evaporation flask stationary, turn on the vacuum pump and let the system get to full vacuum. You are looking for ultimate vacuum and for how fast you reach full vacuum. If you don’t get any vacuum at all, you have a major leak. Most likely you left something open. You can try listening for where the leak is, but the sound never appears to be coming from where the leak actually is. If it takes a long time to reach vacuum, and the vacuum isn’t very good, you might have a slow leak. Inspect all your valves and closures. A prime candidate for leaks is the rotary vacuum seal. Make sure it is clean and installed properly; make sure the O rings are good on the secondary seal; make sure there are no nicks on the seal; make sure the vapor duct is running true. If you can’t find a leak but your ultimate vacuum isn’t very good, your pump may be contaminated with vapor. Run it for a while in free air (no vacuum) to clear it out.

Once this test is complete, start the flask rotating and make sure you still have a good vacuum. A leaky rotary seal will make a ssssht ssssht ssssht sound as the flask rotates. If this happens you need to take off the flask and readjust the seal, the vapor duct, add grease (sorry, manufacturers), etc. You want to do this only after you have done the stationary test because the rotary seal works better once vacuum is attained anyway, and testing rotation second makes diagnosing problems easier. Next install the receiving flask or peristaltic pump take-off and ensure that the vacuum is still good. If everything checks out set the vacuum level to your typical starting value. We use 100 millibar. Vent slightly to raise the pressure.

Setting Up the Run

If your product has been strained and is not too thick, you are ready to go. Suck the product into the evaporation flask using the product in/air vent valve. If your product contains particles you have to open the product in/air vent valve to break vacuum, stop the flask rotation, remove the flask, pour the product into the flask, and reinstall. If possible, it is better to suck the product into the flask rather than to break the vacuum. Firstly, every time you break vacuum there is a chance the vacuum seal won’t re-seal properly, and that is a pain in the butt when you are running product. Secondly, it is technically better from a solvent recovery perspective to start from a vacuum (we don’t think this really matters but the scientists do).

Thirdly, sucking the product into the system de-aerates it as it sprays into the evaporation flask, lessening the chance of boil-over.

Starting the Run

Do not let an evaporation flask full of product sit in a warm water bath while you are fooling around with the equipment. The flask should only be in the water bath when you are actually distilling. During distillation, the product never reaches the temperature of the water bath. It could be as much as 10 degrees cooler than the water bath (because of evaporative cooling). A flask just sitting in bath will reach bath temperature and will boil over when you start distilling because it will be hotter than you expect.

Once your product is in and the peristaltic pump is turned on, lower the flask into the water bath using the lift-jack so that the product level in the flask matches the water line in the bath. If the water line is way below the product line, the flask can wobble quite a bit as it rotates. When you are lowering the flask make sure you don’t smash the flask into the water bath (it is very easy to do).

Now comes the most critical point of the distillation. Turn off your cell phone and make sure your buddies aren’t going to ask you a lot of questions. Concentrate on what you are doing. Make sure you can vent the system quickly. If the vacuum is stable and your product is not boiling, reduce the pressure until it does boil. As the product first starts to boil, you are stabilizing the distillation and getting rid of entrained air. This is where boil-over is most likely to happen. Suddenly, the product will begin to boil violently and shoot through the vapor duct, contaminating the distillation side and ruining your run. This occurrence is common and really, really, sucks. Some products are easy to clean out of the system “in place,” but some require you to break down the whole system and clean it ultrasonically. There is something called a bump-flask, which fits between the evaporation flask and the vapor duct, which can prevent small boil-overs from contaminating your rig, but they don’t fit on our flask. Keep adjusting the vacuum pressure, periodically venting the system if boil-over starts to happen (short vents—less than a second long) until a stable distillation is obtained.

The Main Run

The hard part is now over. The trick is to constantly adjust the level of vacuum so that the condenser is always running at full tilt without saturating. The faster it distills, the better the flavor. Period. This, along with not letting your product hang around in a receiving flask, is the most important rule of flying the rotovap. Side by side, you can always taste which product was made by the person who kept the distillation going fast. For our explanation on this, see Section IV.

If you see distillation only in the bottom part of the condenser that means you need to decrease the system pressure to make it boil more. If the distillation goes all the way to the top you have saturated the condenser. This means that vapor is actually entering the pump system and that you are losing flavor and contaminating your pump. Double whammy. If you saturate, raise the pressure and momentarily vent the system.

If you have a good vacuum controller and a dry vacuum pump, your pump will turn itself off when it is not actually pumping. Your pump should not need to run all the time (unless you are at the limit of what it can pump). If does run constantly, you are probably saturated (or you have a leak, or both).

You should always keep an eye on the evaporation flask to make sure you aren’t boiling over. If you have a peristaltic pump you should always keep an eye on the adapter to make sure the pump isn’t backing up with distillate. If it is, your tubing is collapsing, and you should replace it for your next run. For now, vent the system till the tubing un-collapses and the pump starts pumping again, and resume the run.

For more techniques (like “burping”) see the recipes in the next section.

Ending the Run

Part of the fun of flying the rotovap is tasting the distillate as you go and seeing how the flavor changes from moment to moment. Part of the art of rotovapping is knowing when to cut the distillation off. Invariably, the product is best when the distillation is cut off while there is still flavor in the distillate. Experience will tell you when to quit.

When the distillation is done you have two choices: 1) raise system pressure, suck in new product, and start distilling some more (this only works if you have enough room in your flask for more product); or 2) break the vacuum. To break the vacuum, turn the product in valve to vent, stop the flask rotation, turn off the peristaltic pump, turn of the vacuum (if desired), then remove the flask.

- The Bottle Strength G ‘n’ T

- Brandy and Syrup from Wine

- Cilantro, Thai Basil, Cucumber, and Orange

- Liquor De-Oaking

- Tea Liquor

- Scotch and Peanut

- Habanero Liquor

- Horseradish Liquor

- Blood Orange Concentrate **Legal**

- Housemade Aquavit

- Chocolate Liquor

- Hopscotch

- Other Ideas

There are numerous possible applications of the rotovap in the culinary world. We have listed some of our most interesting and successful recipes, which serve to highlight the capabilities of the rotovap process. Most of these recipes contain special tips and tricks that will help you rotovap other products.

The Bottle Strength G ‘n’ T

The idea of this recipe is to produce a gin and tonic shot at bottle strength (80 proof). To do it we distill lime juice and gin to capture the fresh volatiles from the juice and increase the proof of the gin. We then add acids back to the distillate to re-create the flavor of the lime juice, along with sugar and quinine, the bitter part of tonic water. Why all this? Adding sugar, acid, etc. lowers the proof of the gin. If we want to serve bottle-strength gin and tonic shots, we will have to raise the initial proof. Plus, distilling the lime volatiles gives us a perfectly clear drink that carbonates well (pulp is a carbonation killer).

We no longer serve this drink because it only tastes good at around -18° C. Served any warmer than -15° C and it tastes unbalanced; any colder than -23° C, and it is painful going down. It was hard to get people to drink quickly enough, when the shots were at the right temperature. This same technique, when watered down to 15-20% alcohol-by-volume, produces our perfect G ‘n’ T. We still make that one.

- 1 cup lime juice

- 750 ml Tanqueray gin

With the water bath at 40-45°C and the chiller starting at -20°C and running up to -12°C at the end of the distillation, distill down to 600 ml. Then add:

- Simple syrup to taste

- Quinine Sulfate. Be careful!! Quinine in anything other than minute quantities is poisonous! The legal limit is 83 parts per million of quinine, which is 0.1 grams of quinine sulfate per liter of liquid. You will need considerably less than this. Quinine goes from pleasantly bitter to extraordinarily bitter rather quickly. Make a solution of 1 gram of quinine sulfate in 500 ml of water (or gin) and use no more than 50 ml of this solution per liter of finished product and you will be OK. You will probably like less than half that amount.

- Citric, Malic, and Succinic Acids (2:1:0.1) to taste. This is close to the natural balance of acids found in lime juice. Be careful with the succinic acid. It is unpleasant on its own but adds unmistakable authentic lime flavor to the acid balance when used in small quantities. 0.1 percent is less than what is found in real lime juice, but enough for us. By the way, a 2:1:0.1 citric/malic/succinic mixture stays fresh indefinitely. It isn’t as good as fresh lime juice but is loads better than day-old lime juice.

Chill to -18°C. Carbonate to 35 psi.

Brandy and Syrup from Wine

This is classic distillation with a twist. The idea is to separate a bottle of wine into three parts: alcohol and volatile aromas; the plain water (which we throw away); and sugar, acid, color, oak, etc., which we save as a syrup. The syrup is unlike any normal wine reduction. It tastes fresh and un-oxidized since it is done at low temperature and without air. We were so happy with the first port syrup we made this way that we ran around laughing for 20 minutes. The brandy is also different from normal brandy because it is completely un-aged, retains all of the volatile aromas of the wine, and doesn’t taste cooked. We like to serve the syrup alongside the brandy in a cheese pairing.

- 2 750-ml bottles of sweet wine. Dry wines tend not to work as well because they don’t form a syrup until they have become unpleasantly tannic. We have had good success with port, Madeira, oloroso sherry, and Beaumes de Venise.

With the water bath at 40°C and the chiller starting at -20°C and running up to -12°C at the end of the distillation, distill to 120 proof.

Save distillate. This is the brandy. It is perfectly clear and perfectly delicious. It is best when watered down to about 95 proof. It is more fragile than aged brandy and should be consumed relatively quickly. If you are serving more than one brandies at a time, you might want to add a drop of the base wine to the brandy to make it easy to tell them apart. A touch of sugar or glycerin for body can be added as well (but don’t add enough sugar to perceive sweetness).

Increase the condenser temperature to -5°C and continue distilling until a syrup is obtained in the evaporation flask. Towards the end of distillation, evaporation becomes increasingly difficult because water is tightly bound to the concentrated syrup. You will need to frequently, a technique wherein you briefly allow air into the distillation flask through the air purge/product injection valve (try opening for a two-count). This air adds nucleation sites for bubbles. When your system recovers its vacuum level, your product will boil violently.

Cilantro, Thai Basil, Cucumber, and Orange

This stuff is our favorite product. Fresh, clean, bright. It is at its peak the moment it comes out of the still. It doesn’t taste as good even a day later. After a couple of days it will start to taste brown, like a wilted old herb. If you can’t use it right away, wait a least a month, at which point the taste will be better, but different from the original pure distillation. Just goes to show that high-proof spirits do age in the bottle. Most distilled products, it turns out, aren’t completely stable. This distillation must be done at a very low temperature or the herb flavors are compromised.

Quantities to taste:

- Cilantro

- Thai basil

- Roasted orange slices

- Cucumber

- 1 liter vodka

Blend.

With the water bath at 40-45°C, and the condenser temperature starting at -20°C and running up to -12°C at the end of the distillation, take the mixture to 110-120 proof.

Liquor De-Oaking

The de-oaking technique removes the harsh, non-volatile oak components which, while delicious, can mask the flavor of delicate juices, like apple juice. The resulting distillate is clear and colorless. The residue left in the evaporation flask tastes like wet tree bark. We save it and add a couple drops of it to white liquors to add “instant barrel age.” The result is really quite astounding. We don’t make finished drinks with the instant age. We only use it for demos because were not sure what we think of instant age philosophically.

To de-oak, with the water bath at 60°C, and the condenser starting at 20°C and running up to the -12°C at the end of the distillation, take the mixture to 110 proof.

Many purists will blanch at very idea of de-oaking a fine aged liquor. They are missing the point. We love bourbon straight from the bottle, but when we are treating it as an ingredient, we should feel free to modify it as we please to fit our application. Here is a sample cocktail recipe, one we’ve dubbed the Crazy Kaiseki:

- 1 ounce de-oaked Bulleit bourbon (110 proof)

- 2 ounces Ashmead’s kernel apple juice, kept fresh with ascorbic acid and clarified with 2 grams per liter of Pectinex Smash pectinase enzyme

- 0.5 ounce water

- Pinch salt

Chill to 0°C and carbonate to 35 psi.

Tea Liquor

Distilling tea is interesting because the bitter notes and tannins from the tea are not retained. The flavor is unlike any tea infusion and serves to highlight the difference between distillation and infusion. The trick to getting a good infusion in alcohol is to seal the vodka and teas in a vacuum bag so the alcohol doesn’t boil off. Make sure the mix is room temp before you try to distill or you will have real boil-over problems. It is possible to do this distillation with the leaves in the flask, or with the leaves strained out. Straining the leaves is much, much easier because you can add the mix to the system through the product/air valve without breaking the vacuum and because the leaves cause massive boil-over problems. In fact, tea with leaves starts boiling over again near the end of the distillation run. It’s odd, and we haven’t figured out why yet. Even so, we distill with the leaves in the mix because we think the result tastes better.

- 32 grams tea (We prefer Second Flush Darjeeling because of its fruity Muscat notes.)

- 1 liter ice-cold vodka

Seal tea and vodka and in a vacuum bag at maximum vacuum plus 20 seconds. This ensures we get the most air out of the tea, get maximum infusion, and minimum bag puffing when we steep. Put the bag in boiling water, turn off heat (so you don’t melt the bag on the side of the pot), cover, and let steep for 5-10 minutes. Let bag cool one hour at room temperature. Once cool, with the water bath at 60°C and the condenser starting at -20°C and running up to -12°C, distill to 110-120 proof, or to taste. At the end, the distillate will taste like wet leaves off the ground.

Scotch and Peanut

Nils’ favorite. He loves blended Scotch and dry roasted peanuts, so we distill them together. The resulting distillate is clear and has lost a lot of oak (see De-Oaking above), but is still recognizably Scotch. If you want all the oak flavor, de-oak the Scotch, blend the peanuts with the de-oaked spirit, re-distill, and add the oak back. With and without oak both taste good. This liquor is best after it sits about a week. It would be interesting to compare this product side by side with “fat washed” peanut butter “using techniques that liquor guys have been experimenting with.

- 340 grams dry roasted salted peanuts (Regular roast and unsalted don’t taste as good. We use Planters.)

- 1 liter Dewars White Label Scotch

- 500 milliliters water at 50°C

With the water bath at 60°C and the condenser starting at -20°C and running up to -12°C, distill to 110-120 proof, or to taste. After you have taken off about 250 ml, add the 500 ml water through the product in valve. If you don’t add more water the stuff in the flask gets sludgy and hard to distill. If you add the water at the beginning, the flask is too full and boil-over is a problem. At the end the distillate will taste like peanut skins.

Habanero Liquor

This is another house favorite. Red habanero peppers are some of the fruitiest, more floral peppers you can get. They are also unbelievably spicy. Capsaicin, the chemical that gives peppers their heat, is non-volatile and can’t be distilled. Distilled habanero, therefore, has all the aroma and much of the flavor of a habanero, without the heat. The liquid even smells deadly-spicy. It makes for a very nice drink, especially nice paired with clarified grapefruit juice.

Another weird thing about habanero liquor is how it ages. After a month or so, the “red” flavor of the spirit begins to fade and the drink takes on a more “green” pepper note. After a year it is completely green, like a jalapeno. It never tastes “brown,” like an herb spirit does. We originally stored it in plastic bottles, and a flavor scientist from PepsiCo said the bottle might be absorbing some of the “red” flavors, so we aged a bottle for a year in glass and the same thing happened. One last note: the orange peppers don’t taste as good as the red ones. Get the red.

Warning: the distillate of habanero is the most contaminating of any we do. The flavor gets into all the glassware and lubricant in the system. The entire rotovap has to be broken down and cleaned in an ultrasonic bath after a habanero run. Because of this we do a lot of it in a row and then don’t make it for a while. You also need to be extremely careful about boil-over on this product. Even a little boil-over will make your distillate spicy and ruin the effect.

- 800 grams ripe red habanero chiles (Yes, 800.)

- 1 liter vodka

Blend habanero and vodka on high speed. With the water bath at 45-50°C, and the condenser temperature starting at -20°C and running up to -12°C at the end of the distillation, take the mixture to 110-120 proof.

Horseradish Liquor

Unlike hot pepper, the pungent chemicals in horseradish do distill. They distill so well, in fact, that the resulting distillate can be used in minute quantities to add horseradish flavors to drinks. It is strong, strong stuff. As with all our distillates, the product tastes very clean and pure. It is crystal clear.

- 400 grams horseradish, washed and peeled.

- 1 liter vodka

Blend horseradish and vodka at high speed. With the water bath at 40-45°C, and the condenser temperature starting at -20°C and running up to -12°C at the end of the distillation, take the mixture to 110-120 proof.

Blood Orange Concentrate **Legal**

Hey! Something you are allowed to do! Here we concentrate blood orange juice down to a syrup. We do it very carefully and at a low temperature so the product is unbelievably bright, fresh, and concentrated. This is one of the few applications where the main product is what’s in the evaporation flask. We use blood orange juice, but any juice would work. This syrup is opaque. If you’re looking for a clear syrup, clarify the juice before distilling it.

With the water bath at 40-45°C, and the condenser temperature at -4°C, distill till a syrup of desired consistency is obtained.

Towards the end the distillation becomes difficult because it is difficult to evaporate water off a concentrated syrup. You will need to “burp” frequently (see the description under Brandy and Syrup from Wine).

Housemade Aquavit

This is our nod to Nils’ homeland. Aquavit, by definition, contains caraway seeds, but ours contains nothing but caraway. We use a blend of toasted and untoasted caraway. There are a lot of oils in this one, so when we water it down to 90 proof it clouds up like ouzo, pastis, or sambuca. The perfect skoal shot when served at -18°C.

- 32 grams toasted caraway seeds

- 32 grams raw caraway seeds

- 1 liter vodka

Blend caraway and vodka at high speed. With the water bath at 60°C, and the condenser temperature starting at -20°C and running up to -12°C at the end of the distillation, take the mixture to 110-120 proof or to taste.

Chocolate Liquor

We like chocolate, and we like liquor, but chocolate liquor can be problematic because it is so sweet. Because the bitter notes of chocolate do not distill we can produce a clear, clean chocolate liquor that doesn’t require sugar. Finally, a chocolate martini we can tolerate! This distillation is started a little hot to keep the chocolate liquid, so be careful of boil-over. Use an aromatic chocolate. We use Guittard’s 62%, which is the most aromatic of their line.

- 500 grams Guittard 62% chocolate

- 1 liter vodka

Blend the vodka and chocolate together and heat the mixture over a double boiler till the chocolate melts. Do not overheat or your boil-over problems will be enormous. With the water bath at 60°C, and the condenser temperature starting at -20°C and running up to -12°C at the end of the distillation, take the mixture to 110-120 proof or to taste.

Hopscotch

Eben Freeman does a hop infusion into straight liquor that is similar to dry hopping only much more powerful. Distilling the hops produces an entirely different result because the bitter resins don’t distill. Use hops with an aroma you like. Unfortunately, while we have done this with a variety of hops, we have only used hop pellets (because we were doing it during the hop shortage and because that what our intern, whose idea it was, had on hand). I’m not sure if the isohumulones that cause skunky beer distill or not, but I swear I think the distillate got skunky after a while. Next time we’ll store in light-proof bottles. I don’t have the recipe any more, but we vacuum infused the hops into the scotch (we also did vodka), then blended, then distilled at 50°C.

Other Ideas

We have tried many things, some good, some terrible (Wasabi. Blech). Almost any spice works well but some are quite powerful. Sometimes we vacuum then heat steep spices like tea, sometimes we cold blend like caraway. Pumpkin is interesting, and ages well (it’s not so good right away). Tomato plants were interesting. The liquor tasted like you were standing in a tomato patch. We love that smell. Great stuff but too weird to serve to customers. The poison in tomato plants, tomatine, does not distill; so the product is safe. We did a hot-dog liquor once. Some of the interns liked it. Most of us didn’t. We have tried a wide array of fruits with greater and lesser success. The more a product is aroma based the better the product is. Some fruits, like pineapple, fade fast.

Good luck!