Posted by Dave Arnold

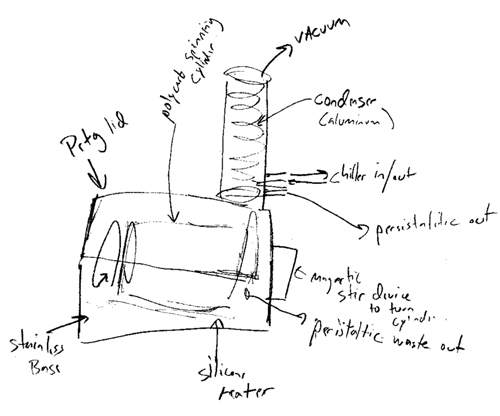

This is not a hamster habitrail. The real plan for the rotovap is in my head, but here's a sketch to give you an idea of how it will work (if you can read my handwriting).

So I’ve finally decided to build my own rotovap. If you aren’t familiar with rotovaps, check out our primer.

Besides the fun of making my own, here are the problems I hope to address:

- Rotovaps are big

- Rotovaps are fragile

- Rotovaps are expensive

- Rotovaps are complex

- The vacuum seals on rotovaps are problematic

- Rotovaps don’t constantly pump distillate (ours does but only because we tricked it out)

- Rotovaps can’t be emptied without breaking vacuum

- Automatic distillation functions don’t make the best product

I have been mulling these problems over for several years. If I lived in the suburbs and still had a shop I would have finished this a looooooong time ago. Strange thing about New York City is that it’s really hard to make things here. Most of us don’t have cars or storage spaces or shops. If you should find something big and cool that you want to take home with you, you don’t have a driveway to throw it into. I guess I could find a shop here, but I’m too lazy. To be honest, unless a shop is inside my house or at my work, I won’t use it.

One thing NYC is blessed with are stainless steel kitchen fabricators, here to serve the huge number of restaurants we have. The photo below shows my mock-up of the base for the new rotovap in 1/16th inch museum board (roughly the same thickness as 16 gauge steel) that I handed over to L and T Kitchen on Allen St. Making a mock-up is easier for me than a drawing, guarantees the model will fit together, and is infinitely easier to explain to the fabricator. They can just cut apart the model and build. I get it back on Monday. More to follow….

cardboard model of rotovap base

finally!!

What’s the total volume you’re hoping to achieve with this one?

Well that is an interesting question Shoshana. The capacity of the base is about 3-3.5 liters (for legal reasons I can’t make it much bigger). With this setup I can do the full 3 liters as opposed to my current 3 liter setup because the lid will give me headroom. Also, I am adding a second peristalitic pump that can pump product out of the base so I can operate continuously without breaking down the machine.

I think I understand most of the apparatus, but I am wondering how you are going to seal the 2 chambers(evaporator and condenser) and how the rotation of the evaporation flask happens. Is it a rotary union or some other magical device. Also how does steam transport occur between the two flasks. I only ask as I am contemplating building one myself.

I am magnetically rotating a tube inside a stationary vacuum chamber.

I wish to make your imaging rotavap

Dave,

I am looking forward to building a system that will do what you want…..

Dutcher

I wish to make the rotavap that yo are imaging rotary evaporator.