posted by Dave ArnoldÂ

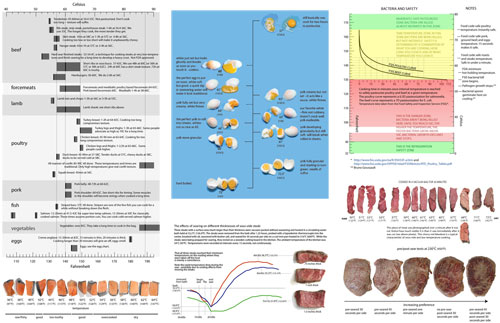

We have had a lot of requests to make last week’s low-temp charts available for download. Here you go:Â

We are often accused of being long-winded. Guilty. When we looked at the sous-vide primer, however, even we thought it was too long—so we decided to break it into parts. We hope to put out a new section every week (or so). This is how we plan on breaking it down:

- I . Introduction to Low-Temperature Cooking and Sous-Vide (Today’s Installment)

- II. Use and Abuse of the Vacuum Machine and Packing for Low-Temp Without the Vac

- III. Vacuum Tricks

- IV. Temperature Control and Safety

- V. Cooking Meats and Poultry

- VI. Cooking Fish

- VII. Cooking Everything Else

Today we have the introduction. It provides an overview for everything else. There won’t be any specific applications or how-to’s in this section. That is for later.

Part I. Introduction to Low-Temperature Cooking and Sous-Vide

- I. Getting the Terms Right

- Low-Temperature Cooking Defined

- Sous-Vide Defined

- II. Some Uses and Advantages of Low Temperature Cooking

- Uniform Cooking, Increased Consistency, and Shifting Control to the Chef

- Shifting Work from Service to Prep (or from Party to Prep at Home)

- Low-Temp for Insurance

- Low-Temp for New and Novel Textures

- Low-Temp for Increased Tenderness

- III. Low Temperature Cooking Disadvantages

- Surface Browning, the Maillard Reaction, and the Challenges of Low-Temperature Cooking

- Uniformity of Texture

- IV. Why do Chefs Use Sous Vide?

- Sous-Vide for Economy

- Storage

- Organization

- Sous-Vide for Effect

- Texture Modification

- Flash Pickling and Vacuum Marination

- Forming

- De-airing

- Sous-Vide for Economy

I. Getting the Terms Right:

Sous-vide and low-temperature cooking are just two of the many techniques and processes that are revolutionizing modern cooking. Despite their growing popularity, many remain confused about the difference between low-temperature cooking and sous-vide—including equipment manufacturers. Between the two, low-temperature cooking is undoubtedly the more important.

Low-Temperature Cooking Defined:

Cooking low temperature does not mean cooking food to a lower internal temperature than is traditional. Low-temperature cooking refers to the temperature of the cooking medium, not the final temperature of the food being cooked. A rare steak has the same internal temperature whether cooked low-temperature or traditionally. Low temperature cooking is defined as any cooking procedure where the cooking temperature is at or close to the desired final internal temperature. There are two basic requirements for low-temperature cooking:

- precise and accurate temperature control;

- a cooking medium which conducts heat more efficiently and accurately than dry air. Water and water vapor are typical, but oil, stock, or any other liquid will work.

By way of example: to cook a steak to an internal temperature of 55°C (131°F), you could either sear it and put it in a 205°C (400°F) finishing oven till it reaches 55°C (131°F) (not low temperature cooking), or quickly sear it and throw it into an oil bath maintained at 55°C (131°F) (low temperature cooking but not sous-vide).

In traditional high-temperature cooking, the temperature of the cooking medium is almost never the same as the desired temperature of the food. That is, while your oven may be heated to 205°C (400°F), your fry oil can to 190°C (375°F), and poaching water to 100°C (212°F), a steak cooked in those mediums can only be considered rare when it reaches an internal temperature of 54°C (129°F). The difference between the desired final food temperature and the temperature of the cooking medium is referred to as temperature delta, or ΔT (pronounced “delta t,†the triangle is the Greek letter delta). You should just get used to referring to ΔT’s –like, “hey, you want that squab cooked to 56°C? Do you want to use a ΔT?â€

Sous-Vide Defined:

In contrast, the simplest way to define sous-vide may be to refer to its French meaning, “under vacuum.†Anything associated with a vacuum machine is sous-vide. In restaurants, the sous-vide process usually (but not always) consists of:

- placing products into impervious plastic bags

- putting those bags under vacuum

- heat sealing those bags

- releasing the vacuum

- further manipulating, processing, or storing

This is where it gets confusing: sous-vide techniques are often used for low temperature cooking, but not all sous-vide cooking is low-temperature cooking. The classic example of this is boil-in-bag meals. The cooking medium is boiling water—not low temperature. Yet, because there is a vacuum process involved, it is sous-vide. That said, sous-vide is very effective for low-temp cooking because food inside the bags neither dries out nor loses flavor during prolonged cooking if proper temperature is maintained. The vacuum bags also eliminate evaporation and evaporative cooling. The temperature of the food’s surface becomes identical to the cooking temperature after a short time.

Chefs and diners alike often confuse sous-vide and low-temperature cooking. Sous-vide must involve a vacuum process; but the food may be cooked at high or low temperatures. About 90% of what cooks want to achieve with low temperature cooking can be achieved without a vacuum.

II. Some Uses and Advantages of Low Temperature Cooking:

Uniform Cooking, Increased Consistency, and Shifting Control to the Chef:

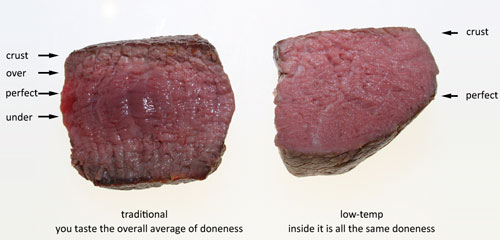

Traditional cooking typically uses a high ΔT. Foods cooked in this manner display an overcooked portion on the exterior. Meat cooked at high temperatures does not have one level of doneness—it is tasted as an average, from the well-done exterior to the less cooked center. Low-temperature cooking is less forgiving, because there is no way to average out errors. In a steak cooked at a low ΔT, the steak retains the same temperature throughout. The difference of 2°C can make a large difference in texture when there is no averaging effect—you need good temperature control (The entire range of steak doneness, from rare to well-done, is only a matter of 14°C (25°F). Luckily, modern equipment easily gives us temperature control accurate down to a tenth of a degree, which means we can cook products extremely uniformly and get them right 100% of the time.

Uniformity can be a disadvantage—no one wants a giant piece of roast beef that is one color all the way across—but most of the time uniformity is an advantage because it leads to increases consistency. Your steaks will never be over or under –always just right. This advantage cannot be overstated, and it applies to restaurants or home cooks. Additionally, because the hard work of reaching the correct internal temperature is being regulated by an accurate piece of equipment, the responsibility for getting the product right is shifted away from the line cook towards the chef who is choosing the temperature and setting the machine.

Shifting Work from Service to Prep (or from Party to Prep at Home):

We can always make more prep time. Service is what service is. Any time we can shift work away from service towards prep we win. Many low temp techniques require more prep time than their traditional counterparts; but are blindingly fast to finish off at service time. The high speed finish derives from the fact that the food is pre-cooked and can be held warm and ready to go, only needing a few seconds of finishing time. Speed finishing is a boon to the home cook as well. Parties are a lot more fun when you can hang out with your guests and all your food is in perfect finish at the same time.

Low-Temp for Insurance:

Low-temp cooking can provide a type of cooking insurance by guaranteeing a minimum doneness. Here’s how:

- 1. Low temp your food to the rarest you want it. The food is now uniformly rare.

2. Cool the product completely.

3. Cook the product traditionally, but focus only on obtaining the perfect exterior because the middle is already cooked. You have insured that the inside is done.

Here are some examples of low-temp for insurance:

- Roasts can be challenging. Often you get a good crust before the middle is done and then overcook the whole piece to bring up the center. Other times, you focus on getting the middle perfect but end up with a poor crust. Low-temp insurance fixes that. Low temp the roast till it is rare and cool it down. Put the roast in a high oven and pull it when the crust is perfect—you have already insured that the middle is done.

- On a beef Wellington it is very difficult to insure that the puff pastry and the beef come out nicely at the same time. Usually the meat is overcooked or the pastry is too blond. With low-temp insurance you sear and pre-cook and cool your tenderloin and then wrap it in puff pastry. Now, you can turn your oven up and just focus on getting the pastry nice and brown since your meat is already cooked.

- Sausages are often poached before being finished in a pan on the grill. This is high-temp cooking insurance. Instead, low temp-cook the sausages (60-62°C is usually good), then finish them on a grill or in the pan. The low-temp pre-cook doesn’t overcook the meat and rely on fat alone to provide juiciness.

- Duck breast is best cooked with low-temp insurance. Pre-cook the breast to 57°C and cool it down. Then just focus on crispy skin.

Low-temp for insurance tends to produce items that have textures and appearances very close to traditionally cooked items, just better and more consistent. Because the products have a traditional feel, many cooks like this technique.

Low-Temp for New and Novel Textures:

Low-temperature cooking also allows for the production of some textures that were traditionally unattainable. Three examples:

- Super-low temp fish: Fish heated at extremely low temperatures, around 50°C or (122°F) to an internal temperature of 42°C (107°F), has a dense, fudge-like or custard quality unattainable with high ΔT cooking. This type of cooking is controversial; many chefs dislike the texture attained with these methods, and some scientists believe the techniques are unsafe. Other chefs believe that the traditional cooking method overcooks fish and that the low-temperature method is best.

- Low temperature braises: In a typical braise, meat with a lot of connective tissue is cooked at a high temperature for several hours. The high temperature and several hours is what is needed to break down the collagen into gelatin. This process overcooks the muscle and dries it out. Luckily, the gelatin re-moistens the overcooked meat and produces a delicious braise. When a meat is under-braised, it seems tough and dry because the collagen hasn’t melted into juicy, water holding gelatin. With low temperature cooking, however, we can hold a tough piece of meat at a very precise temperature for a very long time. If a short rib is held at 6o°C (140°F) it will maintain a lightly pink, medium-cooked color for days. The texture of the muscle fiber itself will also remain somewhat static. The connective tissue, on the other hand, won’t break down over the course of 3 or 4 hours at this temperature—you need to cook it for two full days. At the end of these two days, however, you will have a completely pink, completely tender short rib that is a dream to slice and portion.

- Creamy egg yolks: When you heat a whole in-shell egg in water to 63°C (145°F), the yolk becomes creamy—not runny, not set. One degree lower is a runny yolk. One degree higher is a set yolk. The 63°C egg is a delight and completely impossible to make traditionally. More on eggs later.

Low-Temp for Increased Tenderness:

Low-temperature cooking can also produce meats that are more tender than normal. Enzymes responsible for some of the benefits of dry-aging meat increase activity as the temperature rises. These enzymes are most active right before they denature, between 49°C and 54.4°C (120°F and 129.9°F). Because low-temperature cooking allows meat to stay in this zone longer than traditional cooking, meat is more tender than normal. Traditionally, a large piece of meat heated for a long period of time, such as a roast, remains tender. Low-temperature cooking makes it possible for smaller pieces of meat to be held at these low temperatures for longer periods of time.

III. Low Temperature Cooking Disadvantages

Surface Browning, the Maillard Reaction, and the Challenges of Low-Temperature Cooking:

Low-temperature cooking does not produce crisp, flavorful, brown exteriors, which are usually obtained by cooking at high temperatures. Much of the artistry of low-temp cooking involves getting around this limitation. Some techniques include:

- Using meaty, savory flavors like soy sauce and miso (both are high in umami).

- Quick-searing meats for flavor either before they are cooked, right before they are served, or both. Quick-searing in low-temperature cooking is performed at a higher than normal temperature to develop a brown crust without overcooking the interior of the meat.

- Browning bones, fat, inexpensive pieces of meat, or vegetables and putting them into the vacuum bag along with the main food before cooking. The savory notes of the added pieces permeate the food over time. Roasted fat is especially useful, as many of the characteristic flavors of different meats are generated by the taste of cooked and broken down fats.

Uniformity of Texture:

The biggest gripe people have with low-temp cooking is that the uniformity of texture. Some people say that all low temp food is “mushy.†While it is true that bad-low temp food is mushy, good low-temp food doesn’t have to be. One of the ways to guard against uniformity is to provide texture in the finishing step—usually by searing. Adding crunchy garnishes or cooking portions of the food separately to compensate for the lack of textural variety is another option. A chicken breast cooked sous-vide, for example, might be served with a piece of crispy fried chicken skin (although we have had good chicken this way, we find the skin served this way not as satisfying as good-old crispy skin that is still stuck to the chicken). Lastly, European chefs often cook with a moderate ΔT (usually 10-15 C) to “overcook†the outside of the food and provide some textural variation. Most Americans don’t cook this way because it require precise temperature measurement, precise timing, or both. Most Americans cook with 0 ΔT and add texture in the finishing step.

IV. Why do Chefs Use Sous-Vide? Sous-Vide for Economy and Sous-Vide for Effect

Chefs may use sous-vide techniques and processes for a variety of reasons which roughly break down into two categories: sous-vide for economy and sous-vide for effect. The two approaches are not mutually exclusive, therefore it’s important to thoroughly understand both.

Sous-Vide For Economy:

Storage:

Traditionally, vacuum-packing has been used to enhance the storage life of cooked products. The bacteria that cause food spoilage need oxygen to survive. Since vacuum packaging removes all air (and therefore oxygen) from food, spoilage is slowed drastically if the proper steps are taken. Oxidation is also greatly reduced by utilizing vacuum-packing. Foods like cut apples and artichokes do not turn brown quickly in vacuum pouches. In long-term storage, vacuum bags can prevent the oxygen-produced rancidity of unsaturated fats. Low-moisture products like dehydrated fruit chips tend to stay crispy indefinitely in the low-moisture vacuum environment.

Unfortunately, some bacteria that cause illness (pathogens) are not inhibited by a lack of oxygen. In fact, some of the most dangerous bacteria thrive only in the absence of oxygen. If sous-vide products are kept in unsafe conditions, these pathogens can grow to dangerous levels without the simultaneous spoilage that would normally signal their presence. This is why it is important to adhere to safety rules when using sous-vide.

Organization:

Vacuum-packed pre-portioned foods are neat, sanitary, and easy to organize. Many portions of the same product can be fabricated at the same time and then sealed, which minimizes cross-contamination. The food is handled minimally before being placed in a sterile environment. Retrieving food is easy, and each portion is individually protected from spills and other dangers, such as a raw product dripping onto a cooked product.

Sous-Vide for Effect:

Recently, the unique properties of the sous-vide process have inspired a cooking movement that aims solely to increase the quality of food and achieve special culinary effects. Think of this as sous-vide for effect.

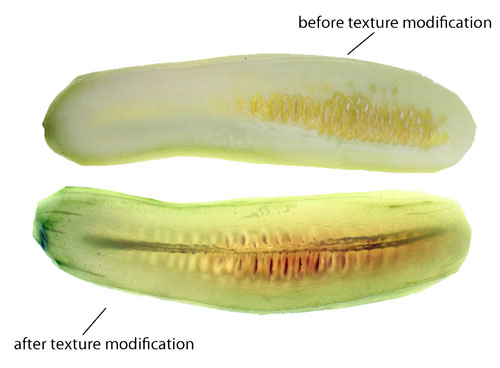

Texture Modification (aka Compression):

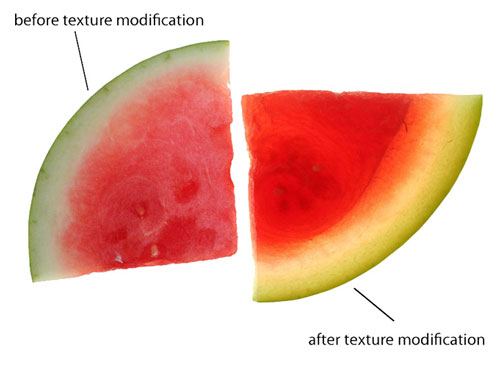

The key to this technique is long vacuuming to get all the air out of the inside of the food. After the food is sealed and the vacuum released, there is an immediate observable change in the product as the voids that used to contain air are compressed. On some products, the effects of compression are accentuated over time (pears become more translucent after several hours). This process can be accelerated by re-vacuuming the sealed bag until the bag inflates with water vapor and then releasing the vacuum.

Porous foods can have their texture and appearance radically modified by vacuum-packaging. Watermelon, for instance, becomes denser, changing from a mealy to a candy-like texture. Pears, cucumbers, and tomatoes become translucent.

Flash Pickling and Vacuum Marination:

Vacuum-packaging foods increases the uptake of flavorful liquids, brines, and colors. The more porous the item, the more dramatic the end results are. For example, a pear can be colored with port in an hour under vacuum. Cucumbers and other vegetables can be flash pickled in seconds. Meats can be brined in much less time than at atmospheric pressure.

Forming :

The pressure exerted by the atmosphere can be used to form dishes. Layers of food can be pressed extremely flat. Once removed from the bag, these compressed layers become easy to slice into beautiful portions. Food can be arranged as in a terrine, vacuumed, solidified, and sliced for decorative effects. Some effects formerly achieved with a simple mold and a weight can be achieved more easily with a vacuum machine.

De-airing :

When thick sauces and purées are blended, they often have large amounts of air whipped into them. Sometimes this air is undesirable. When chefs use modern thickeners and gelling agents, like xanthan gum, trapped air becomes a problem, as it affects the body of the sauce and its appearance (liquids with many air bubbles appear white and opaque). The thicker the sauce, the more difficult it is to remove air. Sauces that contain too much air can be made crystal clear by removing the air bubbles in a vacuum machine.

Any liquid can have all their bubbles removed in a vacuum machine. Place the liquid in an appropriately wide container (not a bag) inside the vacuum machine. If there is too much liquid in the container, the mixture will boil over and create a mess during the process. Close the chamber and introduce a vacuum; the liquid will start to rise and bubble. Soon after, the initial bubbles will break and the liquid will enter a rolling boil. At this point the vacuum can be released and the liquid will have cleared. This procedure is one scenario where there is no need to pre-chill the product being vacuumed because the desired outcome is to have the product boil.

Hate to have the first comment on your excellent work be both critical and substantively trivial, but… chart link not working?

Sorry,

Fixed. Had http written twice.

Loving the new, more detailed primer! The link to the pdf has a mistake though – there’s an extra ‘http://www.http.com’ or something like that after the first http in the tag…

Thanks.

Fixed

The sous vide chart can’t be downloaded.

Sorry, Got it.

Have you guys ever tried using a sonicating water bath for sous-vide prep? I wonder if the sonication could increase the heat transfer rate in the water bath.

Hi Scott,

We haven’t tried it for that. There are some studies out on sonication during cooking as a tenderizer, but I think the studies were inconclusive. Dunno about heat transfer.

Hi Dave, in regards to the sonification while cooking question. My findings were inconclusive due to an inability to control the heat consistently in my older Branson ultrasonic bath. So the effects of sonification are still unknown at this time. The results I did have showed that some additional tenderizing may have occurred, but at lower temps quicker tenderizing did not allow time to break down collagens or fats.

Cool Rick. I quess the problem is you can’t fit a circulator in a small sonicator bath. I have one. I bet I could PID it and check it out. Dunno if I’ll have time.

The link to the chart appears to be broken.

It should be:

http://www.cookingissues.dreamhosters.com/uploads/Low_Temp_Charts.pdf

Thanks Eric,

Fixed.

Thanks, excellent work, looking forward to re-reading.

Commenting on the your discussion of textural modification – Vacuum, or evacuating the sous vide bags if you deconstruct it, is external pressurization – that is, you are applying a fraction of atmospheric pressure to the outside of the bag. Atmospheric pressure on the outside, opposed by the vapor pressure of the food product on the inside.

Caused me to think about forcing the process further. Imagine, if you will, applying higher pressures during the heating cycle. I am imagining a sous vide schema that, instead of a water bath at atmospheric pressure, is at a yet higher pressure. The cooking cycle inside a retort that has, for example, a nitrogen or air overpressure of 4 atmospheres. Makes one wonder what the relationship of pressure is to the outcome, certainly texturally, could be to the final result. Imagine that watermelon at 60 psi?

Sort of interesting in another dimension – the things that we are cooking are usually either animals or vegetables which have always existed at 1 atmosphere of pressure for their lives. The observable, textural changes that you are describing , are the result of application, no the deprivation of that atmosphere. Made me wonder about jumping in with a few more atmospheres of pressure.

Excuse my rambling.

Best wishes,

jhf

Just when you thought it couldn’t get any better…

a plethora bomb of vacuum packed goodness. Cue David Bowie “under pressure”

Thank you.

Hi,

Thanks for sharing your excellent work. Would it be ok to show this chart also in presentations & acknowledge you and your site simultanously? I think this is the most explanatory way to describe the benefits/differences of SV cooking that I’ve seen.

Hi Anu,

I’m Ok with that. I’ll ask the powers that be.

Hey Dave,

Do you mind me doing a french translation of this?

Howdy Nicolas,

Wow! I’m getting translated? Awesome.

It’s easy, I’ll just add “le” or “la” in front of words and they become french. ie: sous vide becomes

“Le sousvide” remember Pulp fiction with

“Le Royale Cheese” 🙂

More seriously, I started. It’s going to take some time but it’s cool that more people have access to it.

It’s good sh**!

Hello Dave,

While I understand you wanting to differentiate “low temperature cooking” and “sous vide”, the battle has already been lost. “Sous vide cooking” now means “low temperature cooking in heat-stable pouches (with or without pulling a vacuum)”. To use “sous vide” to mean “vacuum packaging” or “vacuum processing” will only lead to (greater) confusion. [I actually prefer the term “low temperature cooking” but, again, the battle has been lost. Just as the battle to replace the term “molecular gastronomy” has been lost.]

That “sous vide” means “under vacuum” in French is now just an interesting fact and not a defining characteristic. In 1992, “sous vide cooking” was defined as “raw materials or raw materials with intermediate foods that are cooked under controlled conditions of temperature and time inside heat-stable vacuumized pouches” [Trends Food Sci Tech 7 (1996) 256–262]. Now that we know pulling a strong vacuum doesn’t improve the taste or the safety of meat, fish, or poultry, it seems reasonable to remove “vacuumized” from the definition. (Removing most the air from the pouch is still important to ensure the efficient transfer of heat to the food. But removing enough air so the pouch doesn’t float is sufficient.)

I will use “sous vide cooking” to refer to any “low temperature cooking in a heat-stable pouch” in the next revision of my guide. I also implicitly use this definition in my new cookbook (Sous Vide for the Home Cook), which should hit shelves in the next month or two. I also prefer to use “vacuum processing” or “vacuum sealing” when talking about flash pickling and fruit compression.

As to JHF comment, high pressure processing has been used for decades in the food industry. It is mainly used because high pressure processing can reduce food pathogens and prevent enzymatic degradation. For instance, “peaches and pears processed at 410 MPa for 30 min remained commercially sterile for 5 years” and you can even gel egg whites at 600 MPa [M.S. Rahman, Handbook of Food Preservation, 2nd ed., 2007, CRC Press]. (Atmosphere is about 101 KPa.)

Hi Doug,

The battle has not been lost. Keeping the terms separate is extremely important here in New York City, where you are not permitted to use sous vide without an expensive HAACP plan, but you ARE permitted to cook low- temperature. The key part of the definition you cite is, in fact, ‘vacuumized.’ The vacuum bag is what the health department is in a tizzy about. No one is getting their circulators embargoed — they are losing their vacuum machines. Precise language is important. Just because someone is marketing a product called Sous Vide Supreme that has nothing to do with sous-vide does not mean we should all cave. A lot of our low-temp cooking requires no bag at all. Using a circulator to cook a ham in stock at a precisely controlled temperature isn’t sous vide by any measure, but it is low temperature. Ditto with circulating in fat. Most fish work in the CVap is low temp but not sous vide. The pouch is just one good low-temp technique. Using sous-vide to refer to low temp also muddies the definition when it comes to infusion and the like. It is very easy: there is low temp; there is sous vide. None of the chefs or students we teach –and we teach a lot– have a problem with it.

There is no battle that has been lost –people just haven’t been educated, and it is never too late for that.

Hi Dave,

I agree that your terminology is clear and logical. And I understand that you need to differentiate “low temperature cooking” and “sous vide” for bureaucratic reasons in New York. But I feel that the use of “sous vide cooking” to describe “low temperature cooking in heat-stable pouches” is now virtually universal (even if we can both oppose it on cogent grounds).

For example, if you saw “sous vide salmon with …” on a menu, wouldn’t you assume that “low temperature cooking” has, in fact, been used? Wouldn’t you be surprised if you were served raw salmon that had been vacuum sealed with other ingredients to make a terrine? I would be. And is it really objectionable for someone who cooked a piece of chicken in a Ziploc bag in a precision water bath to call it “sous vide chicken”? I don’t think so. I am fine with someone describing “cooking food in a Ziploc bag in a precision water bath” as “sous vide cooking” because the Ziploc bag does everything that I would want a vacuum pouch to do. (It

prevents: recontamination, the loss of volatile flavor compounds, and the nutrients from leaching out into the water bath.) I’m happy so long as enough air has been removed from the bag that the water bath can efficiently heat the food.

We both agree that cooking food at the temperature that equals your desired doneness is the key. And that similar results can be obtained with or without vacuum sealing the food in a pouch. As for low temperature poaching, I feel that it is better to place a little poaching liquid in the pouch and then cook it in a water bath — why should I use several gallons of stock when I can just put a 1/4 cup of stock in each pouch?

I wish you the best of luck in getting people to use “sous vide” for “vacuum processing/packaging” and “low temperature cooking” for “cooking food at the temperature that equals your desired doneness”. But in my work, I will define “sous vide cooking” as “cooking food in heat-stable pouches at the temperature that equals your desired doneness until the food has reaches your desired tenderness”. But I’m a mathematician and we are always happy to define (or redefine) terms to fit our particular needs.

Hey Doug,

Out here you usually don’t see the term ‘sous vide’ on menus at all.

Chicken is a particularly interesting case; I prefer ziploc’ed to sous vide because I think the texture of chicken is best without the vacuum. I agree that for home, most foods can be cooked with a little stock in the bag, but in a volume situation — cooking off a lot of product over the course of a long service — circulating stock, or oil, or beer, or whatever, can be advantageous. Additionally, large items like whole hams, whole fish, pigs, etc, can be difficult to bag (although I’ve bagged many a pig). We do a lot of cooking in plastic wrap (roulades and cannonballs); would you consider that sous vide? Those techniques are for the next primer installment.

Hey Dave,

Good point, I do focus more on home cooks than professional chefs. Most of the (thousand or so) emails I’ve answered about sous vide cooking are from home cooks and I just spent the last six months writing a sous vide cookbook for home cooks. So it’s no surprise that I look at sous vide cooking almost exclusively from the home cook’s perspective. This is why the first thing I do with raw meat or fish is divide it into individual portions and seal each portion in a separate heat-stable pouch. And if only 4–12 portions are being cooked, then dividing a few cups of stock or oil or whatever between the pouches is much cheaper than filling a bath with stock or oil or whatever. But, for volume service, I can certainly understand you filling the bath with stock or oil or whatever.

If cooking in plastic wrap or a Ziploc bag is functionally equivalent to cooking in a vacuum pouch, then I think it can be called sous vide cooking. What do I mean by “functionally equivalent”? I mean that it must: separates the food from the water bath; promote the efficient transfer of heat from the water bath to the food; be food-safe and heat-stable; and have sufficient mechanical strength. It should also have a low gas permiability to prevent freezer burn on extended storage in a freezer. Since the majority of vacuum sealed pouches have high levels of residual oxygen [Pack Tech Sci 17 (2004) 225–234], then the microbial and enzymatic advantages of pulling a vacuum are questionable. So if it looks like a duck, swims like a duck, and quacks like a duck, then I have no problem calling it a duck.

But we approach sous vide from different directions. You are interested in the best approach for the professional chef. I am mainly interested in the practical application of food science in the home kitchen. With sous vide cooking, my focus is in explaining (science based) food safety and how heat affects meat, fish, and poultry. With this knowledge, a cook can successfully cook meat, fish, and poultry using any method they want.

c’mon, Doug; you are an engineer. Why not file-up the bag with the cooking/poaching medium, releasing excess air before zip-locking and then cooking this package(s) in a water bath? I am a home cook. I even do slow cooking in a steamer bag (which has open steam went holes) to do French scrambled eggs. Just clamp the top of the steaming bag to the top side of my rice cooker.

Actually, in France the exact term is:

“Cuisson a juste temperature” Which means in english “Right temperature cooking”.

Ahh, I see you are with Goussault! I believe he coined that term to contrast himself from Pralus (whose temperatures are quite high). At least that is is what I thought he said. What did you hear?

Yeah, love Goussault.

No they’re not high. Goussault and company (Including Robuchon) separate the sous vide cooking into 3 techniques. I tried the first and third one, I never tried the second one as you need to probe all the pouches and I have only one probe.

Basse/Basse (Low/Low) Meaning you’ll have the cooking liquid at the same temperature as the desired temperature. A steak you want to cook at 57°C would be cooked in a waterbath at 57°C

Traditional low temp process, no probing needed

Haute/Basse(High/Low) You’ll place your pouch in a bath at around 80°C or so and you take it out when the desired core temperature si reached. More like what all chefs are doing already. It make the ouside firmer. Need to probe all the pieces

Etape par Etapes(Step by Step) A mix of both techniques. You’ll place your pouches in a bath at around 80°C for a couple of minutes, then move them to a low temp bath to cook thorougly.

Give a firmer outside and soft inside.

I found all these info and more (In french only, sorry) on a DVD that the BPI (french Publisher specialized in Hospitality) released recently:

http://www.editions-bpi.fr/Produits/C5508.asp

It’s a great DVD. You can check it out on the link Above. there’s is interactive demo here:

http://www.lhotellerie-restauration.fr/Dossier/recettes_en_video/Data/Livre/C5508/index.html

Cheers

N.

Hi Nicolas,

I meant Goussault thinks Pralus’ temps are too high. I know Goussault pretty well cause he does a lot of work here in the US. Some day I’ve got to visit those guys in their plant down in VA. Pralus I only met once when he did a two day seminar at David Bouley’s test kitchen after the sous-vide crackdown here in NYC. His system was pretty strange. He only cooked with 4 different temperatures of water: 70,80,90,and 100C. He uses big delta T’s. I’ve always like Goussault’s approach more.

Oops, my bad. I’m not in the industry myself, I work in Visual Effects. So I don’t meet these guys 🙂

But I agree these temps are very high, I guess Pralus is using the High/Low technique. In the case of foie gras he would still need to take it out when it reaches 54°C core temperature.

Thanks over and over for sharing your research and conclusions on just about everything.

I can hardly find the time lately to read and digest the work and writing you and Nils have put countless hours into. I’d much prefer to have you seem ‘long-winded’ and catch up in time, than to have you omit important details. Long live the wind!

Thanks heaps.

Hey Dave, the restaurant I work was just told to stop cooking sous vide until we get a HAACP. no mention of the vaccum machine in back of the kitchen was mention in the inspection.

Hey Rick,

Where?

Atlanta

Rick,

Crap. If you’d like, I’d like to hear more about what happened. We can do it off the blog.

Congrats on the very helpful charts for sous vide cooking. Pictures worth a thousand words. You have condensed a lot of information in a few simple comprehensive charts. Great achievement!

I personally like the term “precise temperature cooking”. High or low is all relative. What is low to someone is high to somebody else. A case in point: sushi-crazed Japan thinks any temperature high enough to alter the raw state is too high! Wok-crazed Chinese chefs think anything below 100C is too low, they always ask for higher heat and more BTUs for a super fast “wok-hayed” aka “Maillard Reaction” finish.

Canadian food scientist, Pierre de Sorres, who invented the world’s first sous vide cooker appliance (Smart Pot) in 1983. He called his low temperature cooking Freedom Cookery. The basic premise of his invention is “if you cook at optimal core temperature you are doing away with conventional cooking time constraints: food cooked this way can never overcooked but made more safe and tender”.

Whether you call it sous vide, low temperature, precise temperature, optimal temperature or freedom cooking. The most important thing that is happening in the culinary scene is that people are beginning to think in temperature not time.

This is a very profound phenomenon.

Come to think of it, may be we should call it temperature centric cooking and sous vide cooking is merely a sub-branch of it.

Bottom line: We just want to cook safe food that people would enjoy and to be nourished at the same time!

You could get a probe sonicator and put that into your circulator. Not sure how much they cost, we use them to disrupt cells and they look a bit like a stick blender.

Hi Bronwyn,

I have one of those too. They are cool but they send the cooks running. No one can stay in the same room with it. I also wonder if the ultrasound is too focused on one of those things. Maybe worth a shot.

This is awesome!!! Thank you x infinity.

Dear Cooking Issues Team,

I’m working at Saveur in NYC and trying to construct my own bootleg water bath for sous-vide and low-temp cooking. I’m considering purchasing a crock pot and using a combined PID controller-SSR-thermistor from here: http://www.auberins.com/index.php?main_page=product_info&cPath=13&products_id=42&zenid=60df7b67657c14e1ed0f21e07321f6ec

I wanted to see if someone there could give a brief FCI take on this plan, if there’s a better/cheaper way to do this for the amateur. Or if you know where to get a PID-SSR-Thermistor set-up in NYC so I don’t have to deal with shipping. Feel free to email me an answer if you’d prefer. Thanks!

Hi David,

Are you doing this for actual cooking or for proof of concept for an article? Here are some thoughts:

Crock pots have a relatively small capacity and low wattage. The last time I built one of these I used an 1800 watt steam table/soup warmer thingy. You have to make sure you can set the heating element of whatever you use to be on 100% of the time or the PID won’t control properly. The price you quote isn’t bad, but it isn’t great either. It doesn’t do F if you need that. Someone else commented (I think in the last post) on one of these things selling for $159. To do a good job you will want a circulator pump. I haven’t had to get one in a while, but any small cheap pump for RIMS brewing will work. I have used aquarium pumps but I don’t know how long they will work at temperature. If you want to go real spit and bubblegum, wire a bunch of cheap immersion coffee heaters in parallel. Watch out, they leak electricity like a bastard. I got really shocked with them once. Let me know more about your specific needs.

I use a Sous Vide Magic (same as the Auber), a hot plate, and a $10 aquarium air pump (which, crucuially, lives outside of the water and pumps air in through silicone tubing that’s totally happy at any water temperature). I highly recommend it, though the bubbles from the pump are a bit loud.

Hi David

My rig is the Auber you linked, a big stock pot, an immersion heater, an aquarium pump and a FI safety plug (“earth leakage trip” might be a translation…) to address Daves valid point of the immersion heaters leaking electricity (only the American ones, though 😉

I am very happy with the setup. Temperature changes are quick and the uniformity of heat distribution is under my detection limit (ca. 0.3 C).

Dave has a point regarding aquarium pumps & heat: I used it numerous times for meat range (55-65 C) without issues. Although, I went up to 85 C for a couple hours once or twice. This warped some of the plastic pieces of the aquarium pump, but it’s still working… It might depend on the exact build of the pump when (not if) it gives up.

The overall price of this setup was ca. USD 250 and it is big enough to cook for a family and guests.

Added bonus for me is that I can use the Auber to temperature control my (sour)dough (lightbulb in a plastic tub).

Please do not hesitate to contact me directly if you need more information.

Thanks to both of you for the replies. I’m doing this out of my own interest, not for an article. As of now I’m doing some experiments with no-budget sous vide (a pot of water, a thermometer, a bowl of ice water, and a ziploc bag), since I’m unsure about laying out $200+. My hope is to find some sub-$100 workaround, but maybe it’s not possible.

what kind of equipment is used?

Hi Molly,

The upcoming parts of the primer will go into equipment in detail –starting with the vacuum machine.

Hi,

What would be the best time/temp for Beef brisket? I cooked one at 62°C for 48h and it came out horrible. Hard and all the interior connective tissue was still there intact. Any idea? Did I go too high? I never cooked brisket sous vide before.

N.

Hi Nicolas,

I’m surprised that it was that bad. I would brobably do 60 degrees but the extra 2 degrees shouldn’t cause that much of a catastrophe. Typically, the connective tissue will stay intact looking, but will be soft. Do you have any pictures?

I was surprised too as I read in Douglas guide that at The french laundry they cook theirs at 64°C.

I’m going to post a picture on my blog in 30 mins or so, I’ll give you a shout.

N.

Sorry if it appears twice, I tried to post a comment and it didn’t appear. I was saying that I posted the picture on my blog, I you check them out and let me know what you think happened.

Cheers

N.

Ok, I posted the pictures of the horrible brisket. If somebody has an idea of what could have caused the connective tissue to survive for 48hours at 62°C, I would love to hear about what you’re thinking.

You can check the picture at http://www.fiftyfourdegrees.com

As a recent Alum of your FCI Sous-Vide Intensive, I was dying to experiment with some Short Ribs. The results were nothing short of spectacular. We had the Braised Beef Cheeks at Craft last weekend, and my wife preferred these Short Ribs. I cannot think of a better compliment 🙂

I did the following:

1) Pre-sear Short Ribs

2) Sous-Vide with Veal Stock/Red Wine/Mirepoix ultra-thick reduction

3) Cook in a 60C Bath for 48 Hours checking and “stirring” the bag every 12 hours or so

4) Remove from bag and adjust sauce

5) Post-Sear

6) Re-Bag with “fixed” sauce and put back in the bath at 54.4C to keep warm while i prepared other items

7) Slice and devour with sauce

I served them with a wild mushroom risotto and sauteed spinach.

Awesome Jerry. Glad to hear it.

So what’s the lowdown on this Sousvide Supreme machine? You didn’t sound too satisfied with it. I’m, looking for a cheaper solution for my sous-vide needs in Europe.

Dave and Nils,

Thanks for the charts, i think they are a really good teaching tool.

Please let me know if any help. I think I know a lot about sous-vide I work for a French company for more than 15 years I was I R&D manager I can teach to cook sea food, pork, lamb, any kind of meat, I have many recipes. sorry for my English

Hey Dave,

Most everyone has said it all. Thank so much for the work and for sharing. My first short rib sous vide experience met disaster because of not pre searing thus lots of funky smells developed. Since I also have changed to double sealing all my sous vide bags to prevent leaks. When I can find a not too expensive chambered vacuum sealer maybe that will solve the problem. Will you be doing anything for Star Chefs Congress in Sept? I took your class two years ago and it was really interesting. Cheers

Hi Paul,

I don’t know what we are soing at Star Chefs yet.

Hi Dave,

I’ve used your charts as a reference for getting familiar with cooking low temp using vacuuming. I find the charts really useful and would like to have it printed out as a poster of sorts for my kitchen. I think my students will find them useful. May i have your permission to make those posters? We will credit you and FCI on the poster.

Hi Darren,

Sure. Are they Hi-res enough?

Nope they aren’t any chance of you mailing it over? Would like to get into conversation with you about a few other things as well.

Hi,

LOVE this and can’t wait for the rest. Got an Immersion Circulator last week and am going sous-vide mad. (Surprisingly, vegetables have gotten the best results so far…still figuring out proteins).

Question: I use only grass-fed beef, which is far leaner than traditional corn-fed. For traditional cooking methods, grass-fed needs less time and lower heat. How should I adjust grass-fed beef for sous-vide preparation, if at all?

Thanks for simplifying this topic and making it available to all. Very generous on your part. Looking forward to the next sections.

Hi Dave. A couple of matters:

I would like to quote parts of your primer on my blog. But I cannot find any information on this site to point me in the direction of how to get permission.

I find the discussion/distinction between “sous vide” and “low temperature” cooking to be a great help in understanding interpay of these processes on various foods – cooking, tenderizing, flavoring, altering texture & consistency, etc. Keller certainly makes your distinction, as well. But I also find Douglas Baldwin’s discusson re health and safety to be very illustrative. You all have given us a great deal and I am very grateful.

I am using the Sous Vide Supreme with a home vac packer. The vac packer has more limitations for me than the SVS. I have to freeze my liquids in order to get them in the package – a big pain in my backside. Neither can I compress and shape things well like you can with the chamber vac – not a big deal but just a limitation on the fun.

Do you have any plans to add offal to the chart – I am very interested in times and temps for these items – sweetbreads, fois gras, tongue, heart, possibly even liver.

Thanks again for all your instruction and information.

Merridith, blogging at

http://www.fabulousfoodfanatic.com

Hi Merridith,

I don’t think we would have problems with quoting as long as they are cited. You should ziploc your products and not worry about the vacuum sealer. The technique will be in our next installment of the primer. On offal, We have a condensed chart at the school which has Joan Roca’s, Bruno Goussault’s, and George Pralus’, cooking temperatures for everything, including offal, but I’m not sure if I can post it.

Hi Meredith,

I just done a Foie Gras sous vide last week. I usually do it in the oven in a bain marie. This time I rolled it into a balotine in cling film then vacuum seal it and cooked for an hour at 56°C. I came out perfect and delicious. I don’t know about the tongue, last week I posted an article about rolled ox tongue, but I’ve done it in a stock for 6 hours. I think that if I had to cook it sous vide I would cook it for 72 hours at 66°C. Since friday night I have a rolled pork head in the water bath, I’m cooking it for 72 hours at 66°C

Cheers

N.

Hi Dave. I have to say that more than any other article/blog/post/etc. on the web, this one has helped me in my fledgling entry into low temp (and to a lesser extent sous vide) cookery. It is incredible, thank you so much! I then read through the rest of your blog and was blown away with your experiments. This is exactly how I love to think about cooking, as both science and artistry. One question re: The sous-vide and low-temp primer. When is part 2 (and 3 and 4) coming out?

Hi Jeremy,

Thank you so much for your kind words. Part II just came out today. I’m not sure how fast I can get out the rest. I hope to do 2 parts a month. Originally, I wanted part II to include all prep and packing for low temp, but it got too long. Part II is only prepping food to cook low temp without a vacuum. Part III will be about the vacuum.

Dave,

Awesome. Thanks. I currently use the ziploc hand pump vacuum as it only costs $4, the bags seem of higher multi-layer quality, and my SVS put a big enough dent in my wallet for the short term. I do see teeny pockets of air around some irregularities in the surface of meats. e.g. a flat steak. How critical is it that I get these out, i.e. without using any liquid/fat around the meat. (feel free to answer this in part 2b of the primer if you want )

Hi Jeremy,

I don’t think it is that cruicial to get absolutely all the air out. Why no fat in the bag?

I have tried the system he is talking about, its great for keeping a dry item (like an avacado) fresh, or sealing a dry protein for SV, however if there is any liquid you will pump it out and make a mess.

I would guess that is why he is not using fat…

(although i imagine he could freeze the fat or use cold butter)

Just wanted to say thanks for going through all the work to put together this primer. I just finished building an IC this weekend based on plans I found here, http://tinyurl.com/yk2ygt8.

I made a few modifications in the design and used GFCI outlets instead of hardwiring the heaters and pump inside the box. It worked perfectly and any skeptics were quickly silenced by the most perfectly rare steak they’d ever had, low temp salmon, and slow poached eggs. All the cooking temperatures I used came from this primer and everything turned out wonderfully.

I’ll be attending the FCI starting May 26th, need an intern?

Stop on by Jason

That chart is great. Thanks guys. I have a question in reference to the portion of the chart that includes a graph of beef temperature after sous-vide and during and after searing. I’m wondering how you determined that it was a coincidence that the temperatures all reached their lowest points when searing was completed. Also, did you insert the temperature probe and then take readings at 15 second intervals, or did you reinsert the probe every 15 seconds?

Howdy Quysow,

You are tugging on my memory strings. I believe we left the probe in the meat. I just assumed that the fact that the temperature of the meat aat the time searing finished was a matter of luck. I didn’t want the graph to imply I thought there was any causal relationship.

My comments on sous vide refer to those concerned with safety and experiment at very low cost. As both your excellent site and Douglas Baldwin point out, there are elements of time and Temperature and Cost which can be balanced and one of the simplest places to start is with a Crockpot, a $20 Reynolds Handi-Vac device and the ribs recipe from Douglas. The temperature of the Crockpot is not a major concern to any and the the results are fantastic.

http://coffeepotcooking.wordpress.com/2010/06/11/sous-vide-ribs-nothing-better/

In a previous post on the literature of sous vide, I quote from and reference your site on safety issues.

http://coffeepotcooking.wordpress.com/2010/06/11/the-literature-of-sous-vide/

Hi David,

thanks for your work.

It’s always a pleasure and a learning experience.

I took your classes at the school in 2009, when I used to work at Falai, by WD.

Anyway, my question is that I usually cook eggs in the circulator/bath at 61.5 for 70 minutes. The egg comes out good. When the eggs are done, I take them out, ice bath and refrigerate. I was wondering if you have the answers for my questions, please:

1. how long can I keep them?

2. For service, what’s a perfect temp that I can leave my circulator to put the cold/cooked eggs back in the bath and not have them cooked and in a perfect temperature to serve?

3. Once I re-heated them for service, can I re-refrigerate the left overs?

Once again, tks a lot.

Marcio

What about re-heating the frozen foods? My patients love Sous Vide (they have lap-bands) because the meat does not become stuck. I have them re-heat in a sous vide- if they re-heat with microwave or in a sauce the meat dries out. Any thoughts/ideas?

Very interesting Doc. A friend of ours has a lap band and uses sous-vide all the time. He has an immersion circulator, so reheating is a breeze. Most of your patients one have one of those (yet). The problem with sous-vide and lap band patients is that meats that are cooked too long (even if they aren’t overcooked in a traditional sense) can take on a texture (call it fiber-y) that I’m told is problematic for the lap band. First step –don’t cook certain meat too long (like tenderloin).

On reheating, the trick is to not overheat -which is difficult without temperature control. If the portions are consistent, it is possible to develop a recipe to brink a certain amount of water to the boil (simple) put the bag in, turn off the heat, and let it ride for awhile (similar to the recipe for poached chicken that Jacques Pepin got from the late great Danny Kaye).

sv. Why not vacuum pack a meat thermometer in the vacuum packed bag. Probe in center of steak, boil or heat it until the desired temperature internal temperature, i.e. 135 degrees F, is attained, sear it and serve?

Hi John,

I’vr tried that a bunch of times but my thermometers keep getting ruined. The Cooper Industries small digital that is supposed to be waterproof doesn’t survive being vacuum bagged with liquids more than once or twice.

Amazing post.this is very useful topics.

Hi Dave,

‘been cooking some lamb shanks at 60C for 48 hours. Upon then removing from the water-bath, I was greeted by a not so pleasant smell. Eating tomorrow, but not sure if it’s going to be lamb judging by how they smell. Any tips?

John

Sorry for the tardy reply,

Was the bad smell accompanied by a loose or puffed bag? If so, you have lactic acid bacteria growth. That shouldn’t normally happen at 60 C. I see this most often when bags are crowded in the bath. The bags in the center take too long to get up to temperature and bacteria start multiplying and cause the bag to puff and smell bad.