posted by Nastassia Lopez

Every family has their own Thanksgiving tradition. Mine has an annual football game. Nils leaves the country. Dave tries to find the best way to cook a whole turkey for his family.

So far, Dave’s track record has been pretty tragic. The first year, he ruined Thanksgiving by deep frying it on the back lawn at his mom’s house. He burned a patch of grass with spewing hot oil sending one pissed-off stepfather into his bedroom-lights out and all- for a good part of the night.

Two years later, against better judgement, Dave packed up the deep fryer and brought it to his mom’s yet again. He fried it on the patio this time but spilled oil on the flagstone. You know the rest.

Thanksgiving ruined twice.

The deep-fried birds were good, but not worth the familial drama. Perhaps low-temperature cooking would do the trick.  Last year, Dave ran some low-temperature tests on a turkey he stole from FCI’s annual “Happy Thanksgiving Employee Turkey Giveaway” to determine the bird’s optimum cooking temperature.

The breast meat was best when circulated at 64 C but the leg meat was no good. It actually tasted OK but looked raw. Try getting your family to eat raw looking turkey. The leg meat tasted good  at 65 C, which is lucky because by 66 C the breast was bad (dry and stringy). Dave decided to cook his bird at 65 C.

So Dave went uptown to one of the last remaining pollo vivo shops in Manhattan and bought a live turkey. The choice was between a huge (35 lb) wild turkey, or a regular (read: punier) domestic turkey. Guess which one made it home?

He gave the bird one day to rest and pass through rigor mortis. Then he had to figure out how to cook it. Vacuum bagging was not an option because bird bones are mostly hollow and filled with a red marrow that, when vacuumed, is sucked out of the bone and into the meat, making it look uncooked (And no matter how much you tell people it’s cooked, they won’t believe you).

Instead, he filled a stock pot with duck fat and butter, and  jammed the cavity with herbs. He then used two circulators set at 65 C. A hose was attached to one of the circulator’s spouts and pushed into the cavity of the bird so that hot fat was not only circulated on the outside of the bird, but also injected into the center. It was circulated for two hours, chilled in a blast freezer, and then packed it up to his mom’s house where it was finished off in an oven (obviously a deep fryer was out of the question. Fool me twice…).

The results were good.   The only complaint he had was that the  inside of the thighs (where the joint attaches to the torso) were too pink and needed more time, so he sliced that meat and finished it in a pan for 20 seconds.

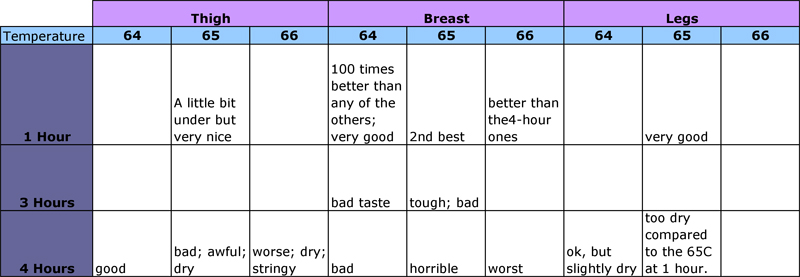

Dave has resolved to do a better job this year.  On Friday we set up a more sophisticated test. We separated thighs, breasts and legs and cooked them at different times and temperatures as follows:

The optimum breast was cooked at 64 C for one hour.  65 C for an hour was also good, and 66 C for an hour was pushing it, but better than any of the breasts circulated for four hours.

The thigh cooked for an hour at 65 C  was delicious, but for regular people, might be a little undercooked. All of the four-hour thighs got worse, drier and stringier as the temperature went up.

The leg was perfect at 65 C for an hour where the one cooked for four hours at 65C was horribly dry.

This Thanksgiving, Dave plans on circulating his turkey in the duck fat and oil again (and he’ll be able to finish it off in a deep fryer because  he’ll be at the in-laws’). The real struggle is trying to find a way to cook the whole 35 lb turkey for an hour if the breast is best at 64 C, and the thigh/leg is best at 65-66 C.  Again, the most important thing is that we serve the whole bird while keeping all of the body parts intact. Because nothing ruins Thanksgiving (or is more un-American) than a table set with an already-carved bird.

How about focused microwave heating to generate different temperaturte zones?

Or more realistic some ingenious way to circulate the oil so it is hottest at the thigh and cooler at the brest?

Likle bags around the thighs, circulator injects warm oil into these plus a few holes to get it out.

set to 66.

Second ciculator set to 62 injecting into birds main cavity?

Key wouold be to keep a constant heat gradient.

If first circulator heats everything up too much, you need some water cooling hose in the oil to generate an equilibrium.

Setting this all up might be difficult, I would try to balance it w/o the turky first. The 66 C circulator needs to be always fireing and the main temp should stay at 64….

good luck

I don’t know much about sous vide but chilling the breast in a big bowl of ice might help? The technique works for roasting but maybe the liquid immersion conducts the heat too fast to make a difference…

For the oil spilling just place the bird in the pot, fill it with water until just covered, and pull out the bird that’s the level the oil should be at, displacement a wonderful thing!

Yeah. I did that. There was some residual moisture on the inside of the bird. That coupled with the fact that the cavity was open from the front to the back caused a geyser effect that sprayed oil like a fountain. That was the first time. The second time the bird was just too big for the pot. Bird plus oil should reach no higher than about half the pot height for safety. If you read the accounts of the turkey frying devotees they are all working with small birds.

Sometimes simple is better… Have you tried cooling the breast considerably beforehand with iceslurrypacks while letting the legs/thighs come to room temp? I’ve found it gives enough DeltaT between the breast and thigh/legs for uniform roasting at 250°F… but then again oil is a much better conductor than air…

Good to hear from you brother! How are you?

I spoke to McGee about this method. I know he used to favor it. If I figure out a way to do it in the circ I’ll post.

Sure do post if you figure it out….

Everything is good and in order, I’ve been following your posts but have been extra busy to post with the restaurant and all…

How about you guys over there?

Everything OK on our end.

Cook separately and then reassemble your frankenturkey with TG!

Some IC’s have external water I/O’s so you can run cold water and use the IC as a cooler. If you run one IC normally use a second as a cooler near the breasts you could create different heat zones. To keep the cooling IC from cooling the entire bath, use a bag to contain it. You could also optimize the cooling over the breasts with a large enough bag.

hopefully that makes sense… i feel like it needs a diagram.

Howdy Jason.

I know what you mean. I’ve already tried a frankenturkey. Post to follow. Nightmare. I have a chiller but it runs PG. I’ve been thinking about differential cooking for a couple days. Will keep posted.

I guess you’re doing the breast at such high temperatures because you’re trying to keep the bird whole?

Obviously this wouldn’t work for doing both the leg meat and breast meat together. . . But I’ve always found turkey breast to be at it’s best at around 60.5C. And I like doing the leg meat at confit temperature (this year, I’ll cut apart the leg meat and then make it back into a kind of terrine with TG).

60.5? I’ve never had any luck this low. How long do you cook?

60.5C is my standard temperature for turkey breast and chicken breast.

Cooking time depends on the thickness of the meat. If it’s one of those gigantic turkey breasts from Fairway, the math says it takes around 6 hours to go from 5C (refrigerator temp) to 60.5C. Figure an hour longer if the meat starts at freezer temp (-18C). If the piece is only an inch thick, one hour is more than sufficient.

Since turkey and chicken breast meats are tender proteins, there is nothing culinarily to be gained by cooking it any longer than the bare minimum time required for thermal equilibrium, right? Anyway, these times are long enough for pasteurization at 60.5C.

Love the blog, it’s always full of interesting info and things I keep telling myself I have to try.

Reading this post, though, 64-66C is between 147 and 151F, right? Does that mean the final temperature of the bird is no greater than 151F/66C?

That seems kind of low, since the USDA says 165 F. Is there a food safety issue at all with a temperature that low, or is just that the texture of the bird could still be “raw” (as you mention above)?

The 165 number is a number that kills pathogens relatively quickly. That’s why its listed in the food code. They don’t trust you to hold lower temperatures for long enough. If you check out the FSIS time-temperature charts for poultry (which are calibrated for 7 log levels of salmonella death in chicken and turkey meats at different fat contents) they provide pasteurization cooking times all the way down to 57 degrees C (although i wouldn’t recoomend this from a taste standpoint). Are you in Piney Grove VA? If so you live near one of my favorite ham producers: Sam Edwards over at S Wallace Edwards.

Love the post! I say the heck with the traditional presentation. Break it down and treat it like two different animals.

Here is a link to what I’ll be doing this Thanksgiving.

http://cuisinetechnology.wordpress.com/2009/11/05/thanksgiving-dinner/

Why not try to break it down , bag with fat and steam it in a combi. Same idea, only a bit more controlled than a giant swirling pot of fat.

Howdy,

Problem is is I’m trying to serve it whole.

Not very high tech, but the best bird I ever made was a variation on the beer-butt chicken.

I brined a 20 lb bird and then let it sit overnight in the refrigerator to let the skin dry out. I then filled a large soup can with a German smoked beer and sat it upright in my smoker (I think I used pear wood because that’s what I could get my hands on).

The beer steam kept the breast moist and cooked it from the inside, the dark meat was only exposed to the smoke and the skin had a nice red pastrami flavor. The smoker temperature was around 250F and I left it in until the breast was around 155F and then let it rest for 15 minutes. The whole bird ended up being done in only 2 hours and every part of it was perfectly cooked.

Reading this, one thing is still unclear to me. The pieces have been held at different temperatures for different lengths of time, but I wonder if there’s a difference if you change the temperature during the time period? For example, if you cook the thighs at 64C for 30 mins then 66C for 30 mins, how different is that from 65C for an hour?

In the post I note that 65C for an hour for the thigh might look underdone but is actually done. I also note that it takes time for the heat to penetrate the meat, which is probably the reason why the joints are the bits that appear a little pink, as those parts have spent the least time at 65C.

I once forgot about a piece of meat in the water bath and it overcooked to that annoying pasty texture. However, I noted that the middle was still ok, presumably because the middle took longer to reach the target cooking temperature than the outer parts. It then struck me that sous vide cooking replaces one variable in the heat equation (temperature) with another (time) that the meat is less sensitive to.

Therefore, the problem might boil down to how to achieve a combination of temperature and time for every part of the meat that would be in an acceptable range.

Assuming that this is correct, and noting that the thighs and legs are less sensitive to timing than the breasts, I would try this variation on the cooking method.

(Assumptions : It takes ~15 mins for heat to penetrate to the inside of the breast, and to the joint sections of the legs; The thighs/legs will be cooked perfectly at 64C for 45 mins and 66C for 30 mins)

1. Get an ice pack cold (I don’t think it’s necessary to freeze but this would depend on the insulation) and add insulation to one side only.

2. Immerse whole turkey in 64C water bath for 45 mins. (So the inside of the breasts and the joints have been at 64C for ~30 mins whilst the outside has been closer to 45 mins)

3. Slap on the ice pack to the breasts, with the insulation on the outside, tie tightly so they don’t interfere with the legs/thighs.

4. Turn up the temperature to 66C for another 30 mins. (The insides of the breasts will stay at 64C for another 15 mins as the cool from the ice packs takes 15 mins to penetrate the insides – this ensures that all parts of the breast experience 64C for a similar period of time)

5. After the additional 30 mins are up, remove the turkey and let rest for another 15 mins (assuming this is the time for heat to reach the insides). So the outside of the thighs/legs would have experienced 64C for 45 mins and 66C for 30 mins before cooling. The insides of the thighs/legs would have warmed up as the heat penetrated the meat for the first 15 mins, then experienced 64C for 45 mins, then 66C for 30 mins before it finally cools down.

Of course this all depends on the assumption that 45 mins @ 64C and 30 mins @66C is a good temp profile for the legs/thighs!

I didn’t know that about the marrow in bird bones! Greta articles where I learnt a lot, ta.

Love the beginning of this story lol G-Rod in his room pissed about the burnt grass…HAHA

Only theoretical:

Cool breasts with ice (or something more efficient) while legs get to room temp. Then encapsulate the bird excluding legs in an insulating wrap. I’m not sure what materials to use (maybe some food grade bubblewrap/foam or that emergency blanket stuff?). Then vaccum deal and circulate.

Must find correct relationship between starting temperatures and insulation properties.

seeing that photo of the circulators in the butter stock made me cringe-do you have a problem with dairy solids building up inside, if so how do you clean?

love this site by the way, completely changed my view of FCI, I wish you guys were there when I was

We haven’t had any problems. It is a little harder to clean the circulators afterwards.